Mdt. Giuseppe Vallarelli compares traditional and digital workflows for refractory feldspathic veneers in terms of speed, quality, and precision.

Shared by CreaMED team from The Excellence srl dental clinic and Mdt. Giuseppe Vallarelli.

Introduction

Digitalization of dental production protocol is one of the most common topic among dental professionals, who start to actually see their laboratory or clinic become more and more virtual.

At the moment there is too much perplexity towards this “drastic” but unavoidable change. Now, digitization in fact is involving almost all dental companies but there is skepticism about the real precision of this kind of products.

Understandable are doubts of who has consolidated his own activity in years making medical devices by their hands. Today, with digitalization, the physical contact with prosthetic teeth is becoming virtual.

“The scanner reproduces carefully details and edges like the plaster? We can have distortion or inaccuracy in the digital workflow?”

We receive this kind of question daily.

This study case, realized thanks to the collaboration of Dental Laboratory of Giuseppe Vallarelli and Dental Clinic The Excellence srl, shows that the digitalization of the workflow presents a lot of advantages if we consider the time of realization of the refractory feldspathic veneers – which represents one of the best examples of precision in the dental field.

The need to digitize a part of the dental workflow is born from the mdt. Giuseppe Vallarelli’s need to improve the efficiency of his laboratory to make refractory feldspathic veneers quickly but without ruining the esthetical aspect.

It is known that this kind of manufacture is still the best expression of dental craftsmanship and it requires long preparation for dental models. In this case, we thought to digitize these phases to allow the dental technician to bypass the realization of Geller model. Then, once he receives the dental impression, he can directly build the feldspathic veneers with the dental ceramics.

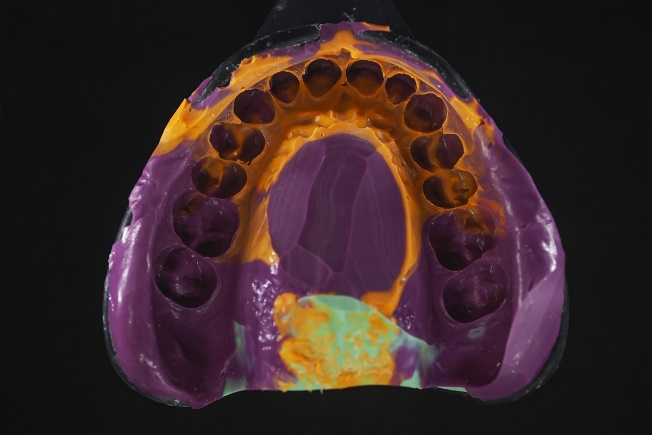

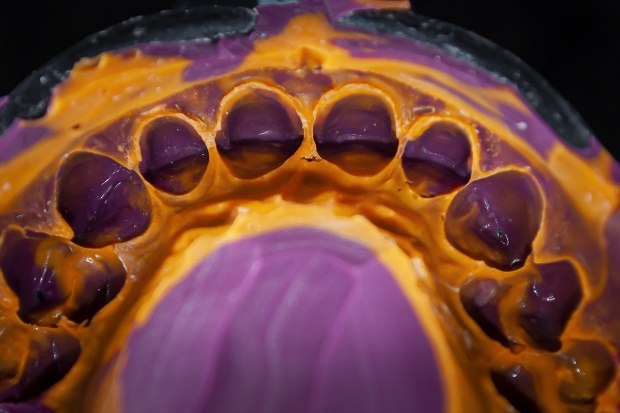

3D scanning the impression

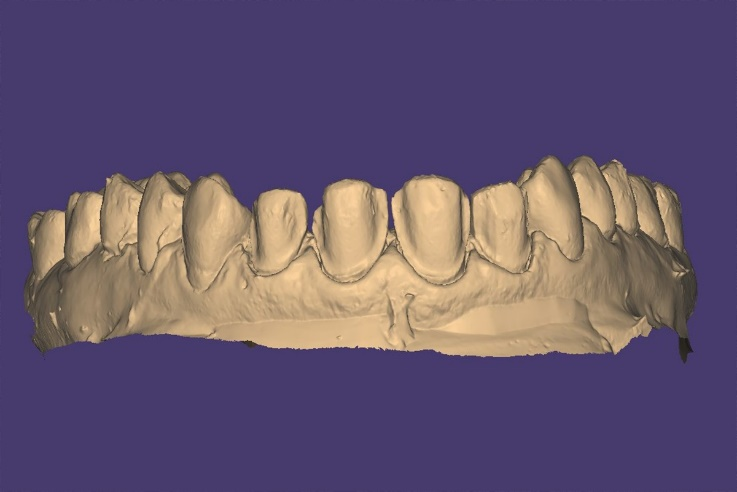

Once we received the impression from the dental clinic, we scanned it with the dental lab scanner Autoscan DS-MIX without the use of spray, and turned it into a digital mesh.

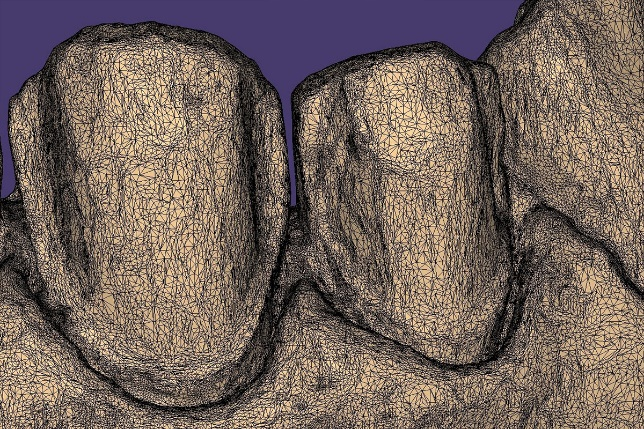

The supervision of mdt. Giuseppe Vallarelli was very important because he could carefully judge the precision and the accuracy of the generated mesh. Above all, he could evaluate the finish line edges, crucial for the success of the veneers.

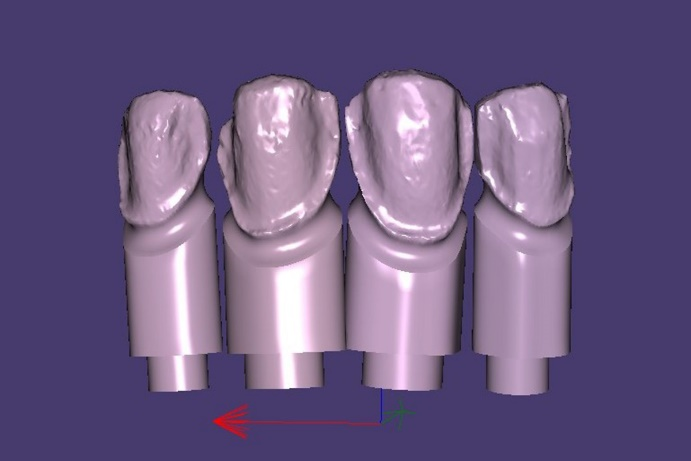

Through this scan, it was possible to make the virtual model with removable dies.

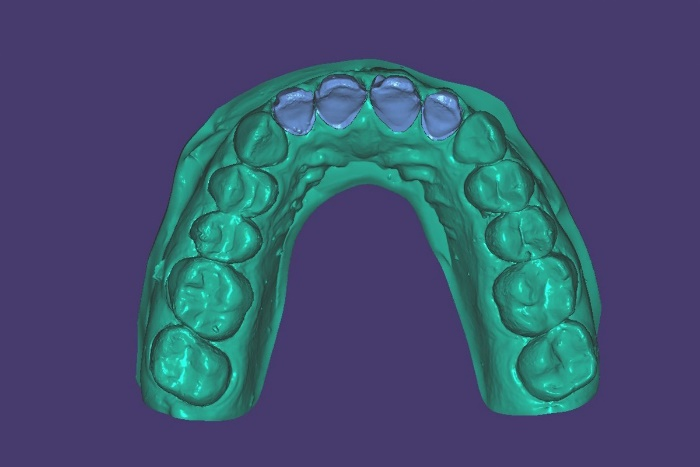

3D printing the dental model

Then, it was quickly 3D printed with the Accufab-D1.

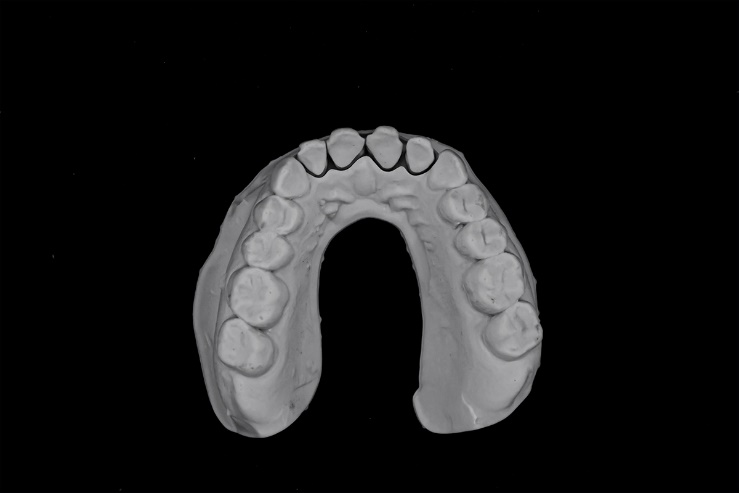

At the same time, staff made a master model in plaster to verify the precision and use it as a comparison tool for the 3D printed dental model.

After only an hour, mdt. Vallarelli had on his workstation: a master model, a working model, and dies ready to be duplicated in refractory material.

After duplication, the refractory dies had the same fitting as the 3D printed dies in the 3D printed dental model.

Through this simple step, we were able to pass from dental impression to ceramic step in only two hours. We can say that the active working time of the dental technician was only half an hour.

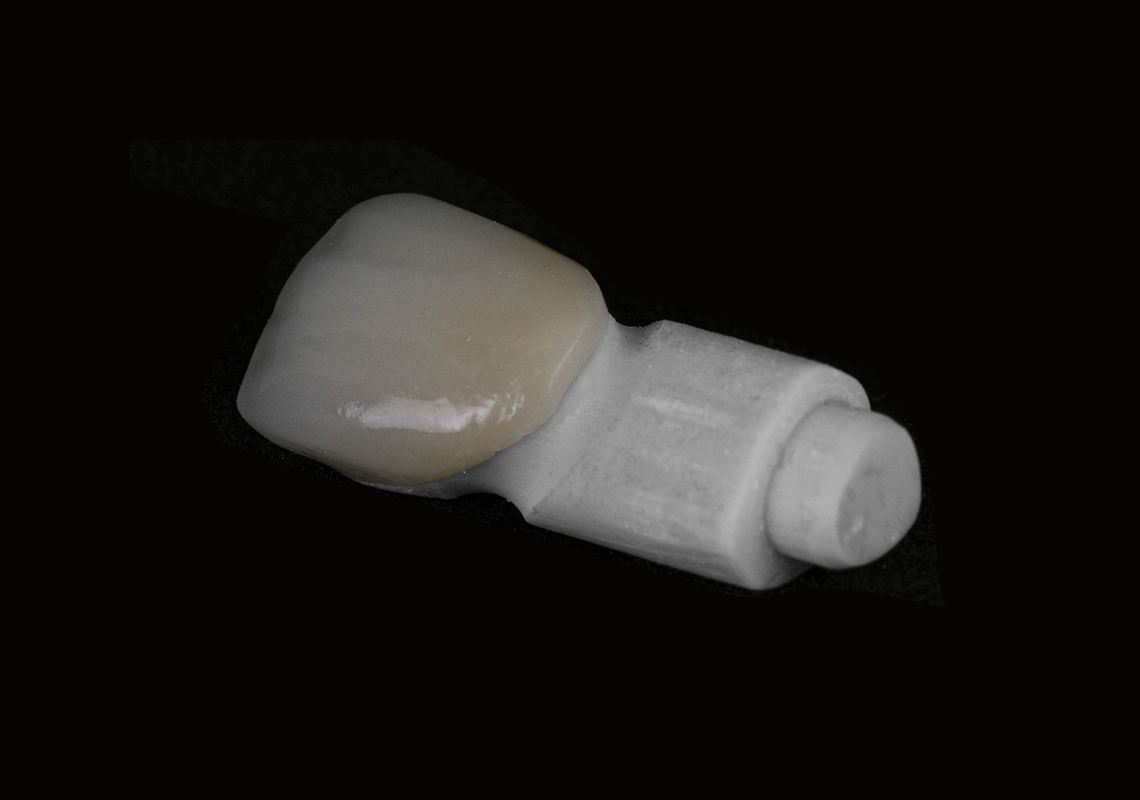

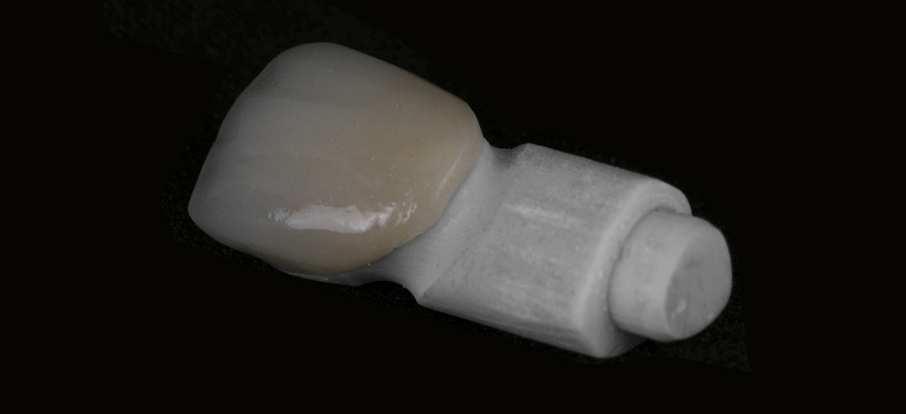

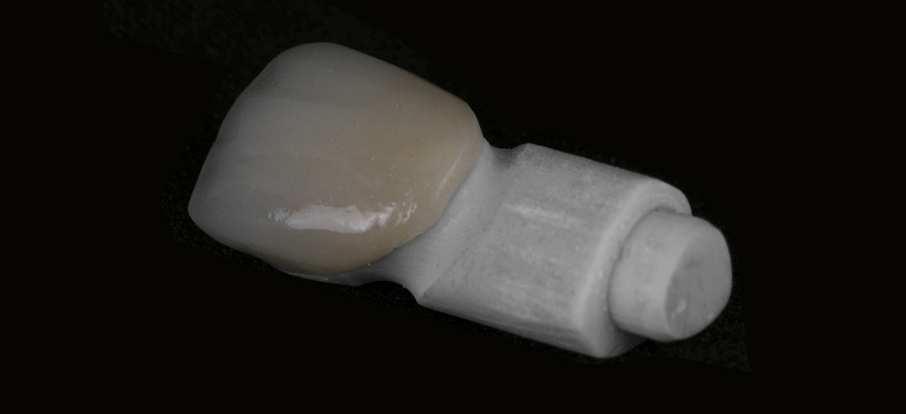

Fitting the refractory feldspathic veneers

After ceramization and refinement, the team released the veneers from the refractory material and fitted on the working dental model through 3D printied dies. This enabled us to verify the fitting with the model and adjacent teeth, and occlusion accuracy.

Later on, to compare the obtained digital result with one from the traditional workflow, the team positioned the veeners on the master plaster model doing the same checks already done on the printed model. The result was the same from the point of view of fitting as well as contact point and precision of the marginal line.

Conclusion

In conclusion, we can say that the technology is becoming increasingly a solid reality in the dental field. Despite the perplexity of dental professionals, we can demonstrate the best precision of these tools compared to the traditional workflow.

Replacing traditional materials with new generation materials speeds up the workflow, without compromising on quality and precision point of view. This demonstrates that knowledge is essential to placing new technologies and materials side by side with the workflow.

Many thanks to The Excellence srl dental clinic and especially mdt. Giuseppe Vallarelli and his staff for sharing this study case, for their availability and knowledge of materials. Thanks for leading us in a critic and constructive way during this experience.

ENG

ENG