In the past and even now, full mouth occlusion reconstruction has been a highly challenging process, requiring multiple visits and long-time treatment periods. The results were often not very satisfactory. However, thanks to the advancements in digital technology within the dental industry, such as intraoral scanners, 3D printers, and the widespread use of implant surgery, the treatment outcomes and patient experiences have improved significantly.

In a recent case study conducted by Dr. Abdelrahman Khalaf and Dr. Kirollos Hany from the Faculty of Dentistry at Assiut University in Egypt, they utilized digital technology to help a patient achieve full mouth occlusion through implant surgery. This innovative approach has shown promising results and enhanced the overall treatment experience for the patient.

Fig 1: Dr. Abdelrahman Khalaf and Dr. Kirollos Hany

Case Profile

The patient had been experiencing teeth loss in both the upper and lower jaw, resulting in impaired mastication and pronunciation. He desired dental restoration at a reasonable cost.

Making Treatment Plan

Upon the patient’s arrival, the dentist utilized the Aoralscan 3, a rapid intraoral scanner developed by SHINING 3D known for its exceptional speed and accuracy, to capture his intraoral data. Considering both financial constraints and the oral condition of the patient, the initial treatment plan involved restoring his upper jaw through implant surgery and fixed restorations. The patient is aware that restoration of the lower jaw will be pursued once his finances allow.

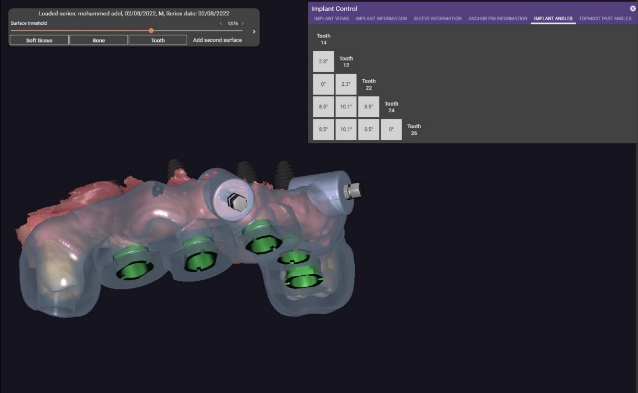

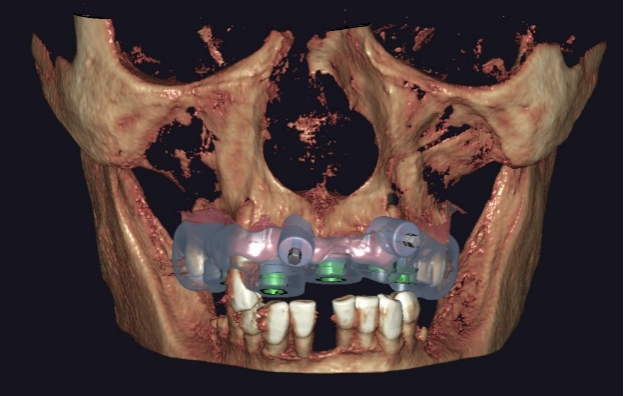

Make Surgical Guide

Based on the intraoral scan data captured by Aoralscan 3 and CBCT data, the dentists utilized exocad to design a surgical guide. 5 implant bodies intended for placement at positions #14, #12, #22, #24, and #26. Additionally, two retaining nails were incorporated to secure the surgery guide in the soft tissue of the upper jaw (Fig 2, Fig 3). Subsequently, AccuFab-D1s printed the surgery guide using SG01 resin. This printing technology offers users an enhanced workflow that is more intuitive and user-friendly while also providing faster print speed and improved accuracy (Fig 4).

Fig 2,3: Design the surgical guide

Fig 4: AccuFab-D1s printed the surgical guide

The Implant Surgery and Upper Restorations

After all preparations were completed, the implant surgery begun. With the aid of a surgical guide, the dentist was able to precisely place the implant bodies at the predetermined location, with accurate angle and depth, resulting in a more controlled surgical process.

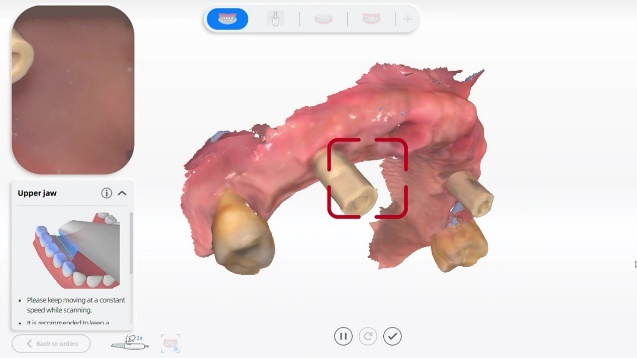

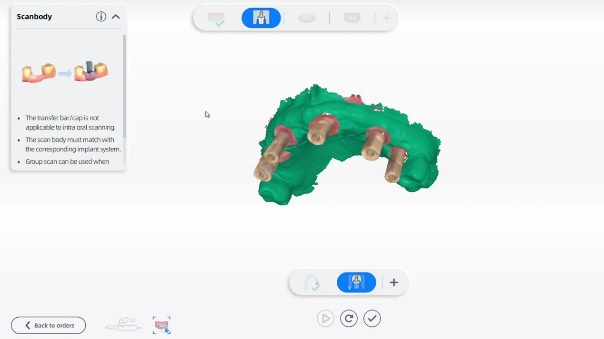

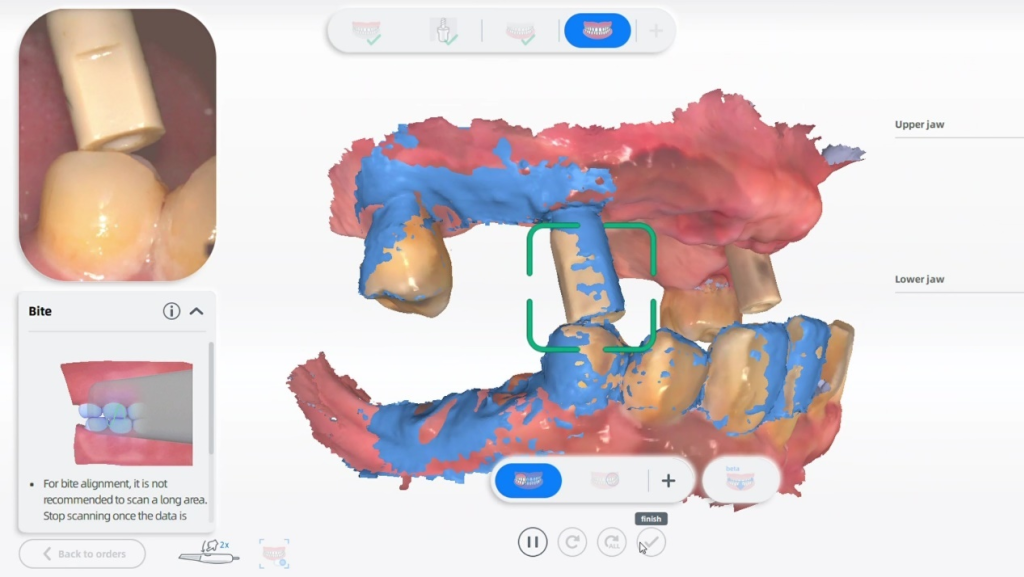

After a waiting period of several months for wound recovery and optimal osseointegration, the patient returned for upper restorations. Once again, the dentists performed an intraoral scan, initially without scan bodies. Subsequently, they deleted the data related to the implantation site, placed the scan bodies in position, and conducted another scan to obtain completed intraoral data (Fig 5, Fig 6, Fig 7).

Fig 5-7: The intraoral scan before upper restorations

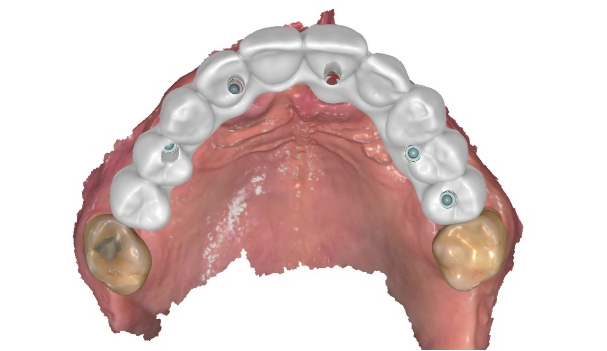

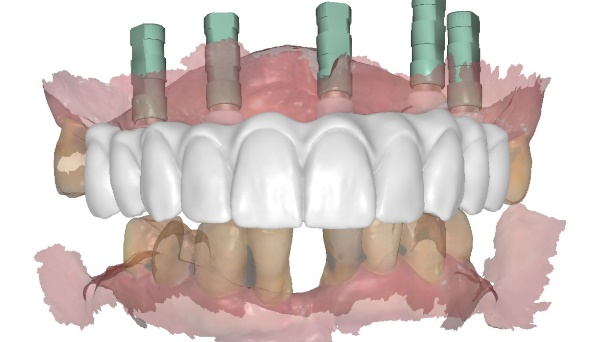

The upper restorations were designed based on intraoral scan data, a long bridge spanning teeth from #15 to #25 for a total of 10 teeth. Occlusion was confirmed during the design process (Fig 8, Fig 9).

Fig 8,9: The design for upper restorations

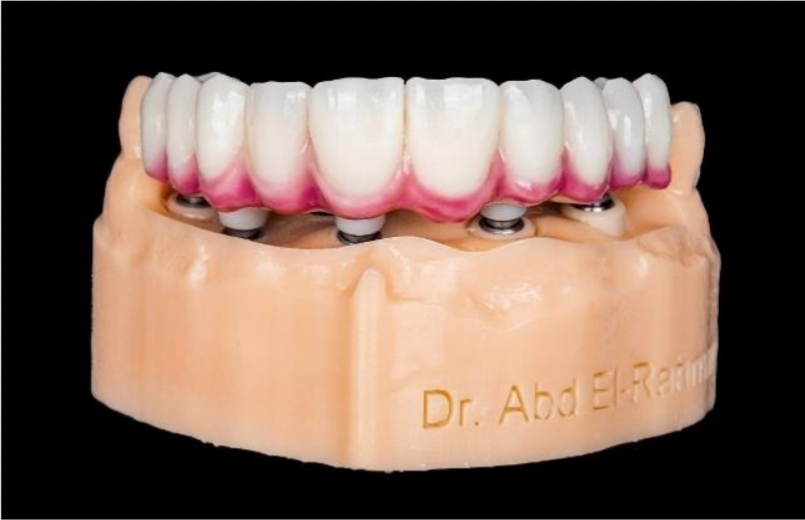

Model Try-in and Final Delivery

The inspection model was 3D printed, and the restorations were milled from zirconia. During the try-in process, dentists had an opportunity to make any necessary adjustments to the restorations on the model prior to patient arrival (Fig 10, Fig 11).

Fig 10,11: Model try-in process

Once all preparations were completed, the patient returned for treatment, allowing the dentist to seamlessly affix the restorations without significant modification (Fig 12, Fig 13).

Fig 12,13: The patient returned for treatment

Following treatment, the patient expressed high satisfaction with their new teeth as they harmoniously blend into his smile and exhibit a pleasing aesthetic appearance (Fig 14, Fig 15, Fig 16).

Fig 14-16: The full mouth occlusion reconstruction is finished

ENG

ENG