By using a 3D scanner for anterior teeth injury treatment, a dental team in Hangzhou was able to perform same-day digital dentistry on a patient.

Overview

A patient at the Hangzhou Greentown Stomatological Hospital was diagnosed with anterior teeth injury. After performing a root canal, the medical team prescribed him fiber post-endodontic therapy and E-max crown restoration.

For this restoration, dentist Dr. Zhang Chao used the AutoScan-DS-EX. He scanned the patient’s impression and was able to shorten the entire treatment process to one day.

Same-day digital dentistry: the process with a 3D scanner for anterior teeth injury

Several steps were involved in this patient’s post-endodontic treatment.

1. Preoperative diagnosis

Firstly, Dr. Zhang did a preliminary shade match.

Pre-op photos

1st shade matching

2. Tooth preparation

Secondly, Dr. Zhang prepared the concerned tooth and performed a second shade match.

2nd shade matching after teeth preparation

3. Impression taking

After preparing the tooth, the patient was ready to get his impression taken.

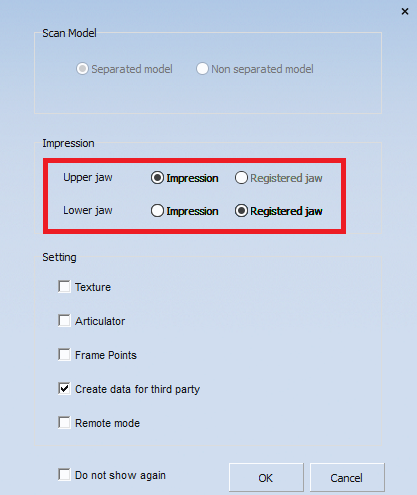

In this case, the dentist used alginate for the impression. Since this material is prone to deformation after around half an hour, it was preferable to make an opposite with plaster to ensure reliable and accurate data. (Note: It’s also possible to scan the alginate impression immediately after taking it.)

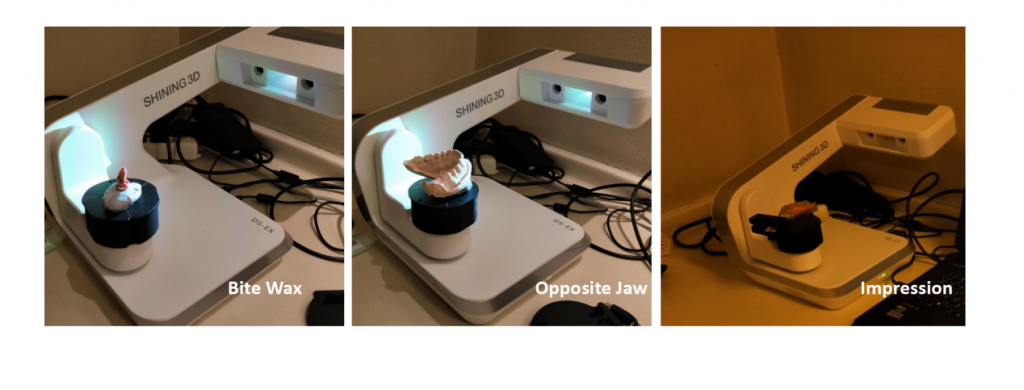

4. 3D scanning the impression

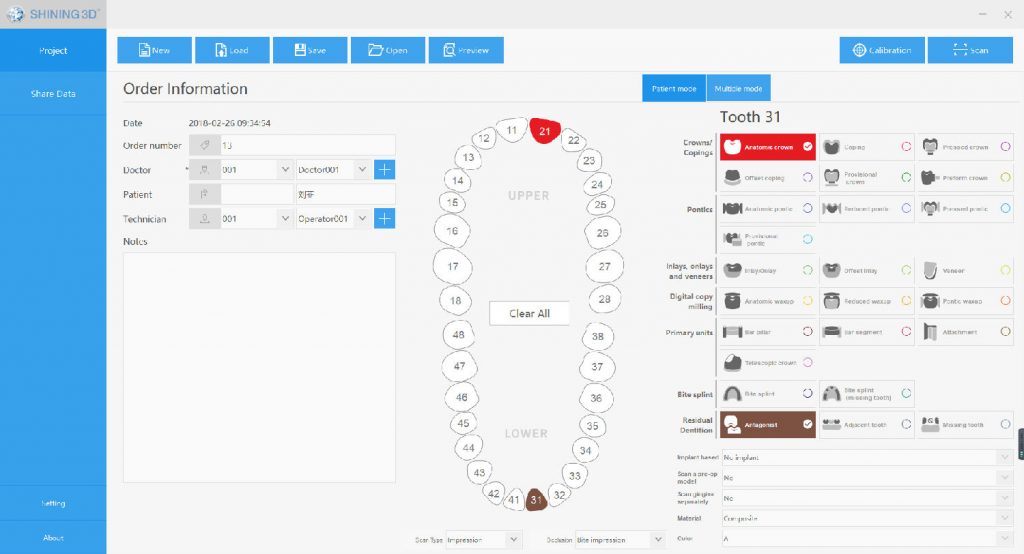

Dr. Zhang opened DentalScan to create a new order. He was then able to select the involved tooth, the prosthesis information, scan type, and jaw relation record, among other elements.

The software then displays prompts for the entire 3D scanning process. It semi-automatically operates the AutoScan-DS-EX.

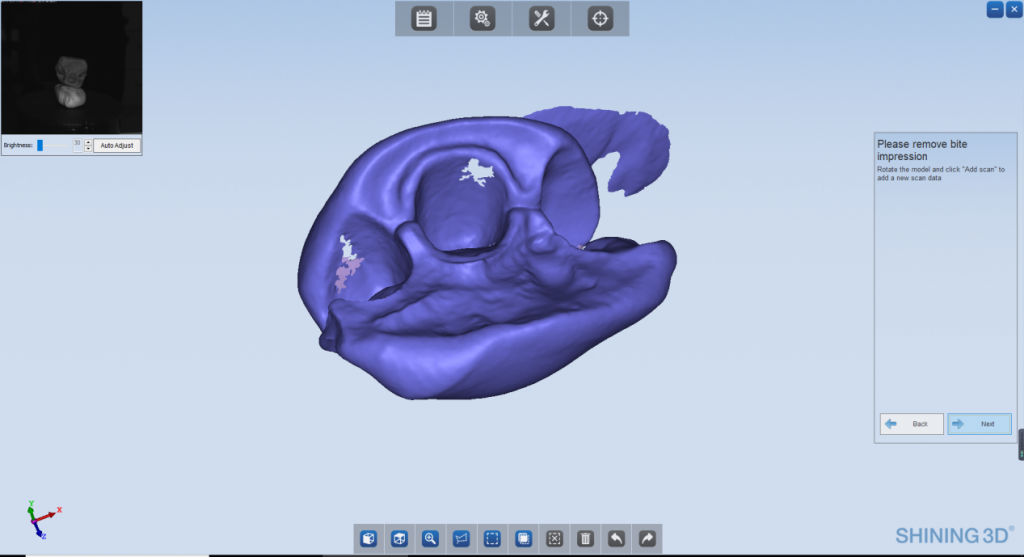

Captured Jaw relation record data

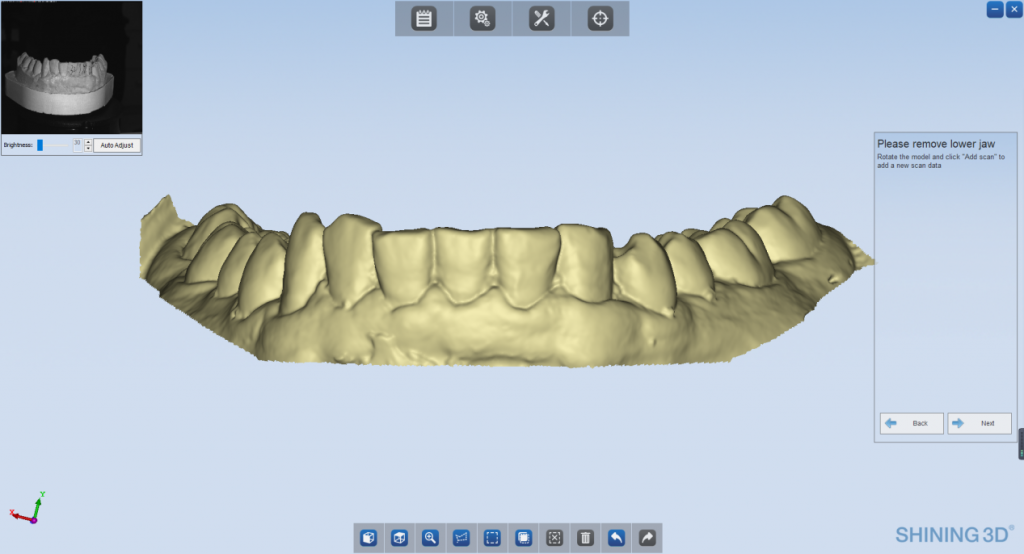

Data of the opposite jaw was real-time displayed on the computer

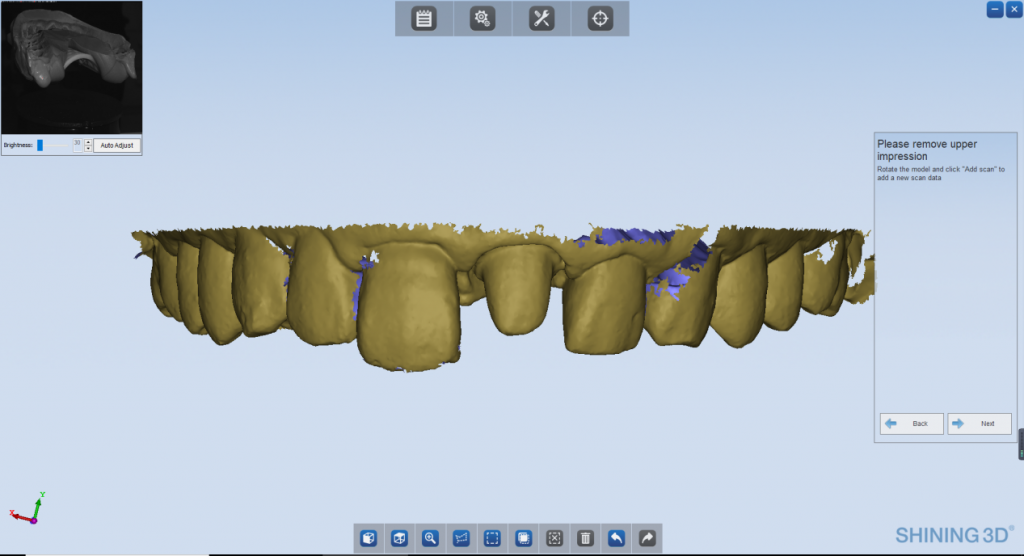

Captured Impression data

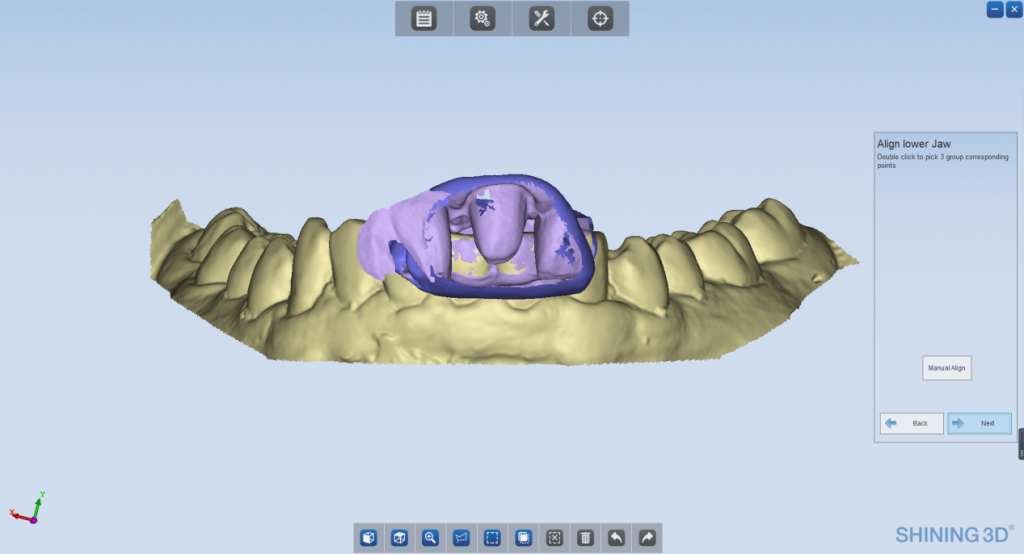

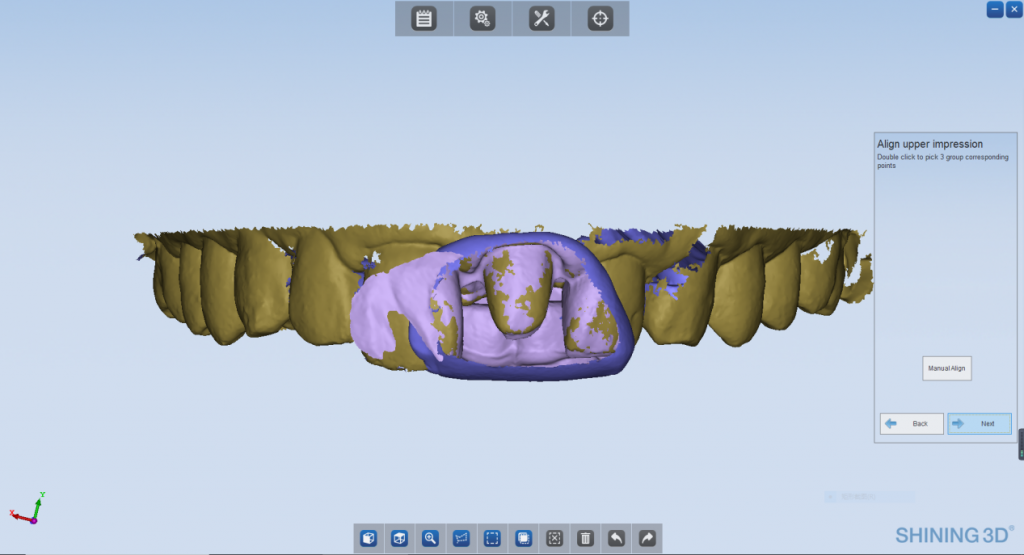

-Aligning

Aligned the upper and lower jaw models with bite wax.

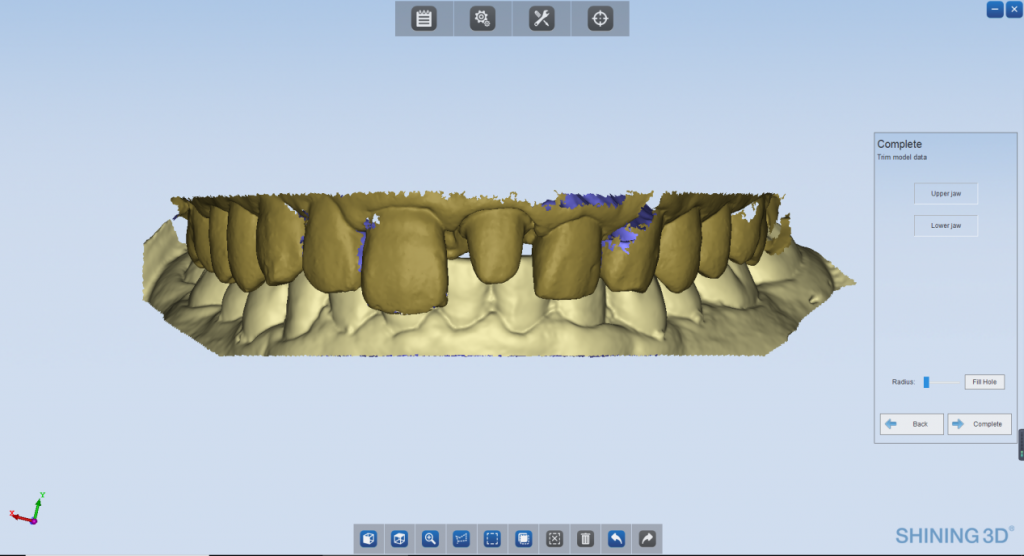

Once all three elements were successfully scanned, it was possible to prune the data (remove noise and redundant data).

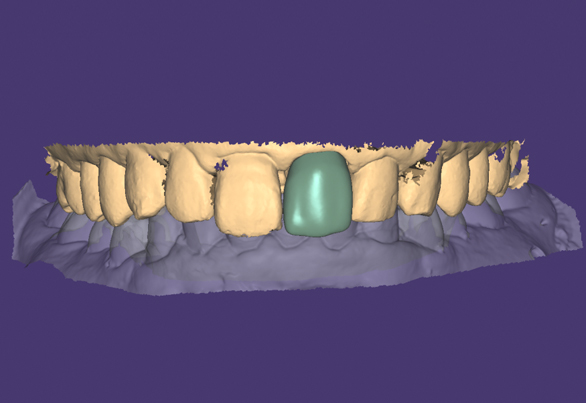

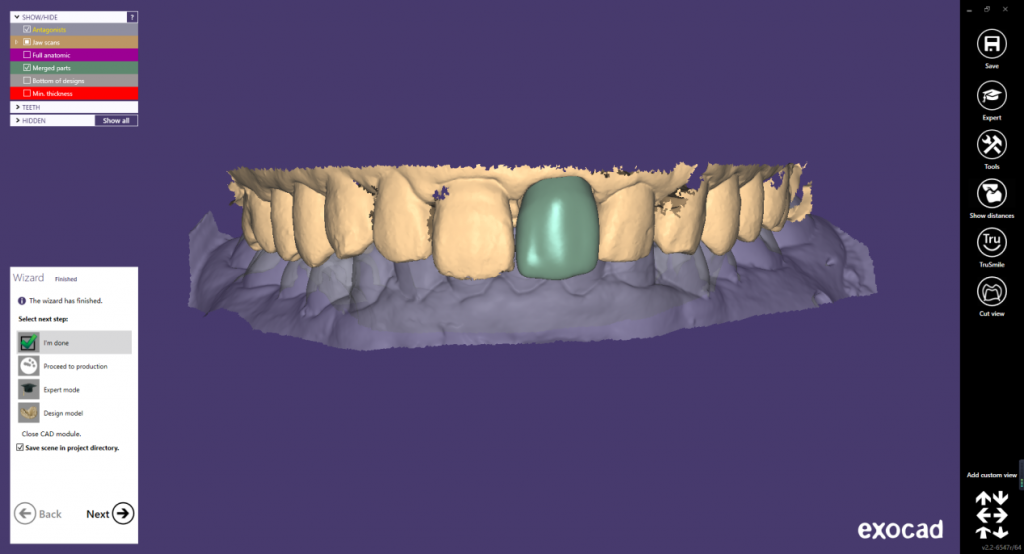

5. CAD design

With DentalManager, scanned data was then directly shared with a CAD designer who could download and open it in exocad.

6. Digital processing and manufacturing

After the design was completed, the file was sent to a dental lab for milling and production. This eliminates the traditional process of transporting the dental model from the clinic to the dental lab.

7. Finalizing the treatment

The patient was happy with the natural-looking result. and satisfied with the short treatment time.

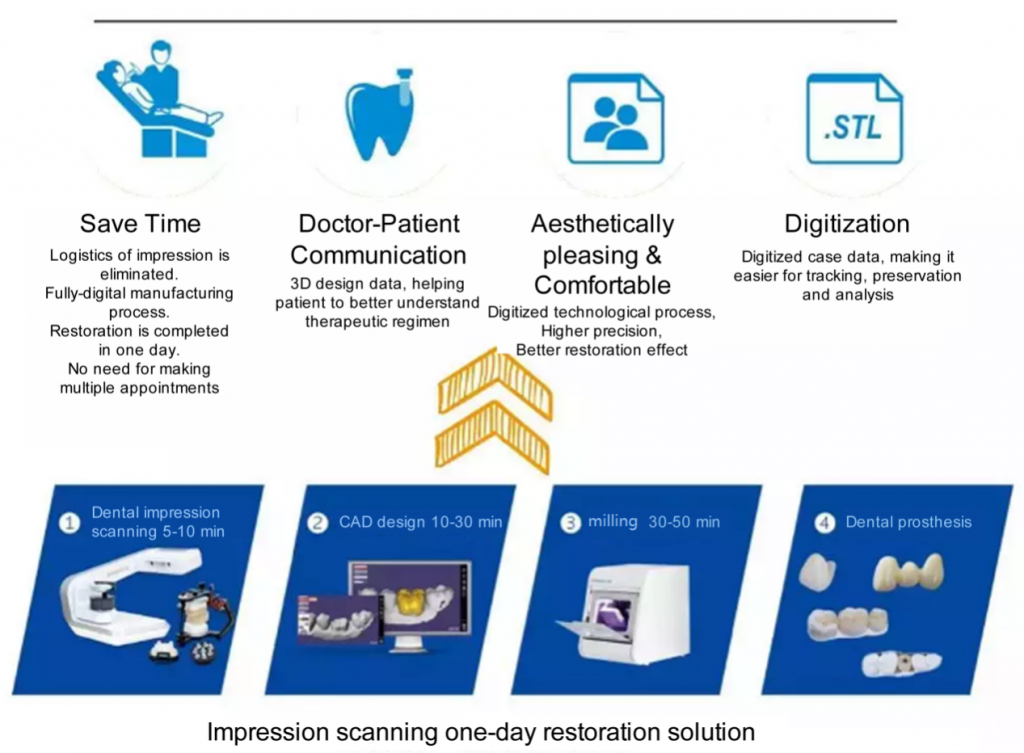

Advantages of using a 3D scanner for anterior teeth injury restoration

Save time and obtain better results

The compact AutoScan-DS-EX makes it quick and convenient to capture complete, accurate data to manufacture crowns. Compared to the traditional dental treatment process, digital dentistry is simpler and smoother all while providing even better restoration results.

Improve patients’ experience

By completing the restoration in one day, the patient doesn’t have to make multiple appointments. Also, the 3D data helps patients better understand therapeutic regimens, improving doctor-patient communication.

Easier CAD design

DentalManager software integrates seamlessly with mainstream CAD software in the market and supports public cloud sharing. The dentist can send the scanned data directly to CAD designer and then for digital manufacturing. The traditional plaster model has been transformed to digitized data, which is easier for tracking, preservation, studying, and analysis.

ENG

ENG