Table of Contents

The implant is a treatment by inserting the implant body into the lower or upper jaw to provide firm support and install restorations to restore chewing function and aesthetics. For patients with insufficient bone mass, implant surgery to obtain long-term success would be a challenge for both dentists and patients. For these kinds of patients, we can increase bone mass through bone grafting, achieved by taking autogenous bone pieces from other parts of the body or using allogeneic bone pieces for transplantation. Autogenous bone grafting is generally considered the most desirable option because it reduces graft rejection and infection risk.

Today’s case comes from Dr Abd El-Rahman Khalaf and Dr Kirollos Hany (Fig 1). They are dentists of the Faculty of Dentistry at Assiut University, Egypt. They used digital technology to perform a perfect autologous bone graft in a bone-deficient implant case.

Fig 1: Dr Abd El-Rahman Khalaf and Dr Kirollos Hany

Case Profile

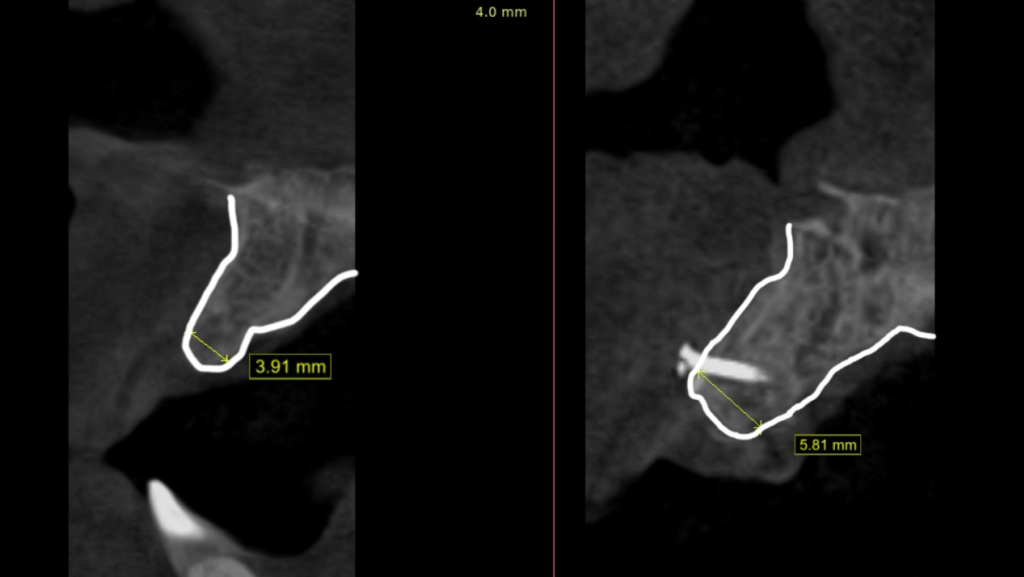

A patient who lost her incisor teeth in an accident wants to utilize implant technology for restoration. However, due to inadequate bone mass for long-term implant stability (Fig 2, Fig 3), a direct implant surgery might fail. To address this, Dr. Abd El-Rahman Khalaf and Dr. Kirollos Hany initially conducted a successful autologous bone graft procedure, followed by implant surgery.

Fig 2,3: Before autologous bone graft, the CBCT showed that the thickness of the bone plate was approximately 3.9mm, which was insufficient for performing implant surgery in the anterior area

Treatment Process: Intraoral Scan and Design Process

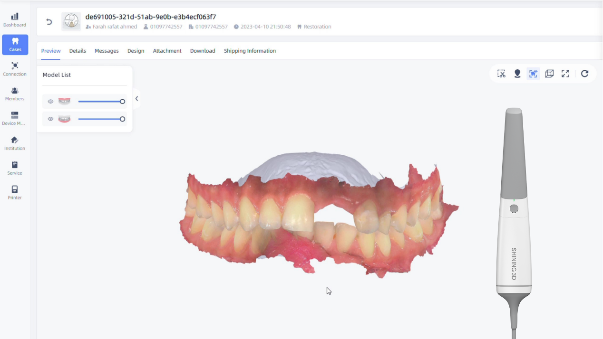

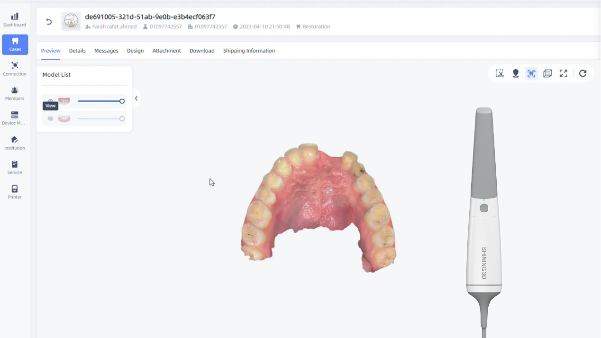

The dentists captured the patient’s intraoral scan data using Aoralscan 3 (Fig 4, Fig 5). It is a smart intraoral scanner equipped with powerful software, including AI scanning and multiple dental functional modules.

Fig 4, 5: The front view and the occlusion view.

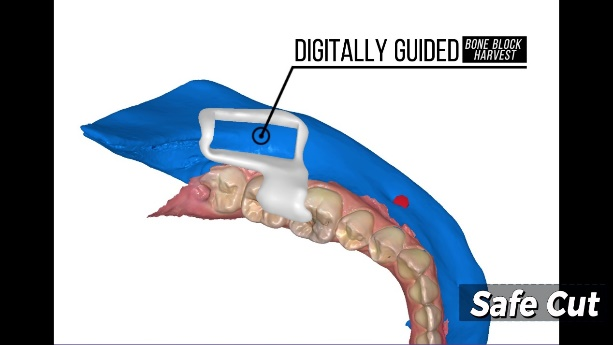

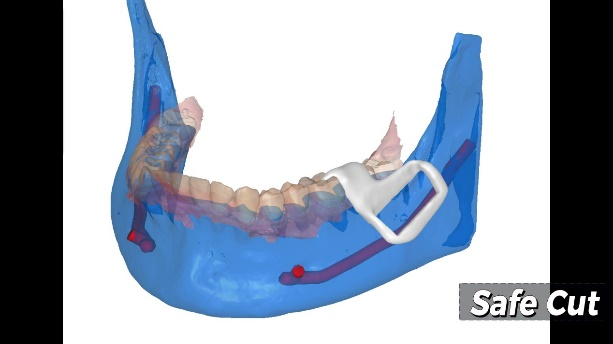

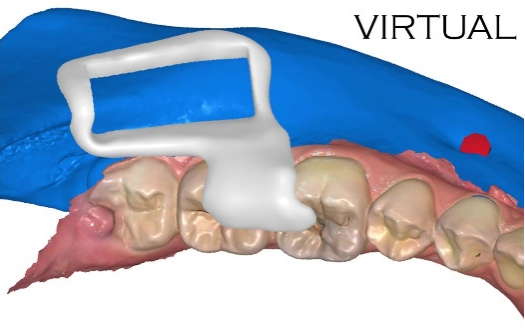

Second, the intraoral scan data were imported into dental software to design a safe-cut surgical guide. The surgical guide will be used in bone removal from the posterior mandible area and placement in the anterior area (Fig 6,7).

Fig 6,7: The design process of the safe-cut surgical guide.

Treatment Process: Printing

The digital safe-cut surgical guide was printed by AccuFab-D1s with a third-party resin. The AccuFab-D1s, produced by SHINING 3D, is an open system that is compatible with multiple third-party resins, offering more choices for end users.

Fig 8,9: The surgical guide, printed by AccuFab-D1s, ensures a safe and precise surgical process

Treatment Process: The Surgery Process

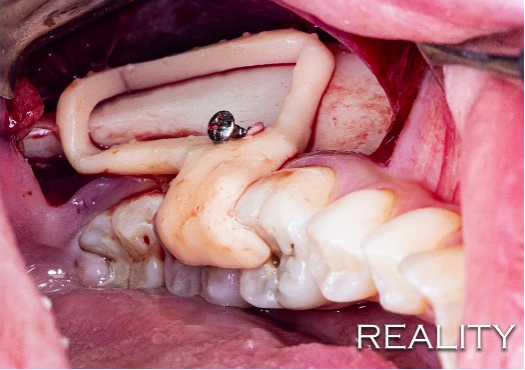

The printed safe-cut surgical guide was placed in the patient’s mouth, fitting well and exposing the surgical area. The accuracy of the intraoral data captured by Aoralscan 3 and the guide printed by AccuFab-D1s contributed to the precise fit of the surgical guide (Fig 10, 11).

Fig 10: The virtual surgical guide in design software

Fig 11: The printed surgical guide inside the patient’s mouth

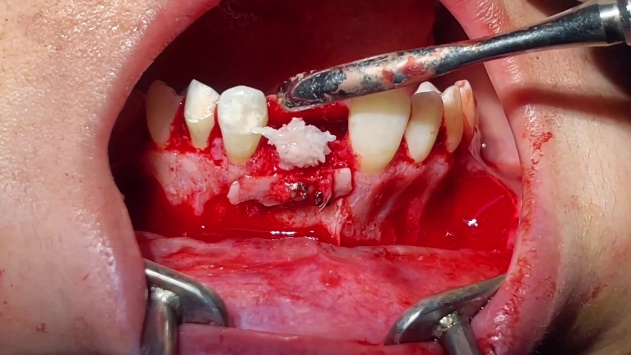

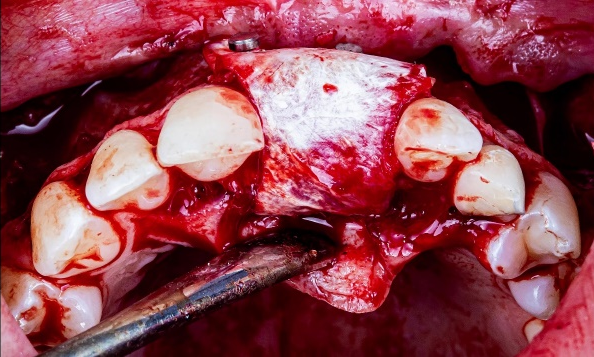

Then dentists performed the autologous bone graft surgery. There are several steps.

Fig 12: Remove the bone with the guidance of the safe-cut surgical guide.

Fig13,14: Place the bone in the teeth’ anterior area.

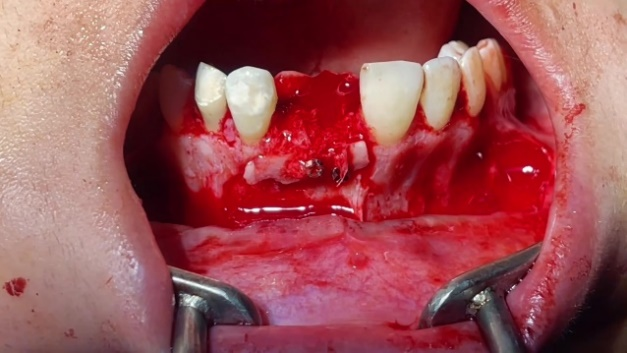

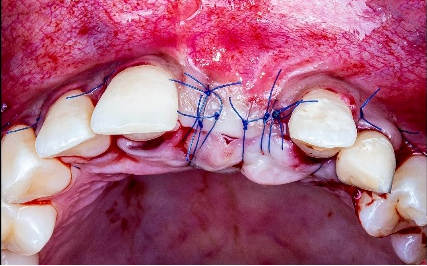

Fig 15,16: Put a biological membrane to cover the bone & stitches in the operative area

Treatment Process: After Autologous Bone Graft

A CBCT was taken again to check the changes in bone mass, which showed an increase in bone plate thickness from 3.91mm to 5.81mm after the surgery (Fig 17,18,19). This increased thickness is a prerequisite for implant surgery in later stages.

Fig 17,18,19: The comparison of the thickness of the bone plate before and after the surgery

Comments from Dr Abd El-Rahman Khalaf and Dr Kirollos Hany

The surgery is successful thanks to the super accurate intraoral scan and the printed safe-cut surgical guide. The digital technology used in this case ensures that everything goes smoothly, with minimal mistakes and a smaller incision.

ENG

ENG