This case explores the use of 3D scanning in immediate loading. We use the Aoralscan 3 from SHINING 3D to capture teeth, gingiva, and scanbody.

Introduction

Intraoral scanners, mainly used to take digital dental impressions, are now an essential component of modern dental practices. They allow for more accurate restorations and more efficient relationships with labs.

Digital impressions also improve the patient’s experience by reducing chair time and the overall number of visits, especially for implant cases. Intraoral scanners make it easy to get an accurate impression without material contact and the complicated workflow of traditional impression-taking.

Basic patient information

The patient was an elderly man who presented with several fixed prostheses in the upper and lower jaws, and an implant-supported restoration at #36. The dentist planned to extract teeth #31, #32, #41, and #42, to then immediately place implants and make a new restoration.

Surgery

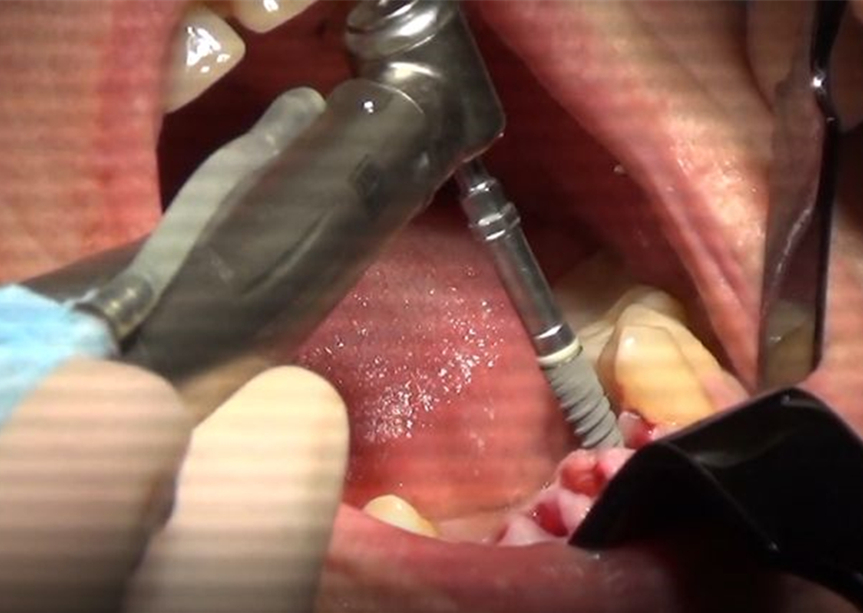

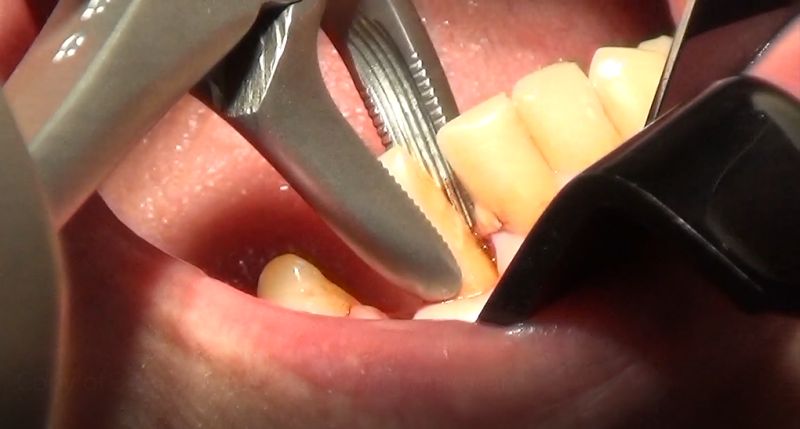

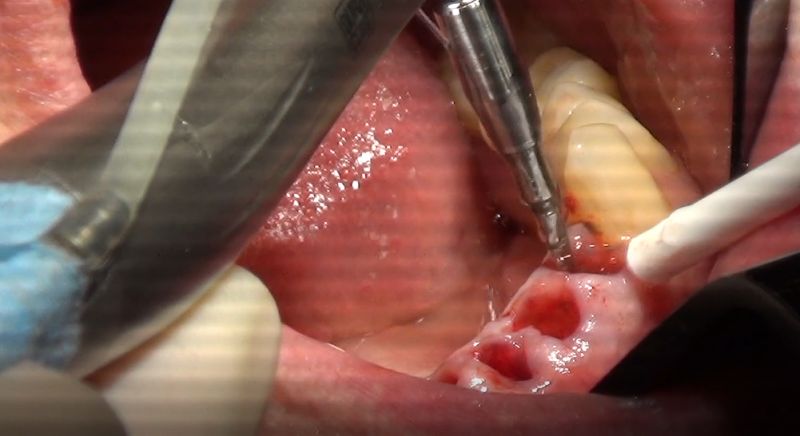

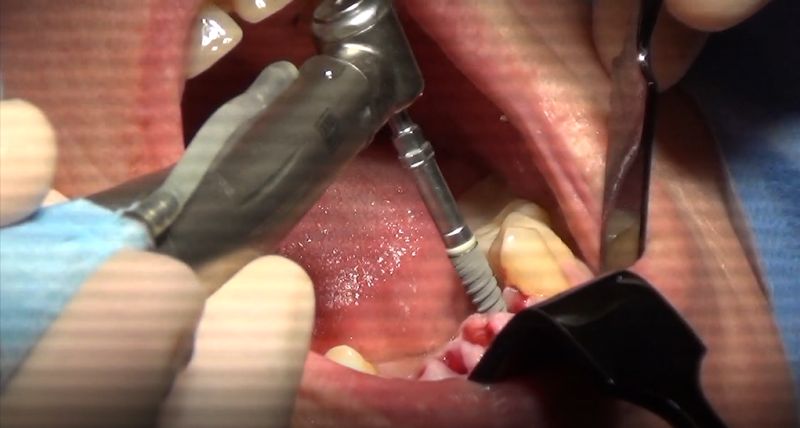

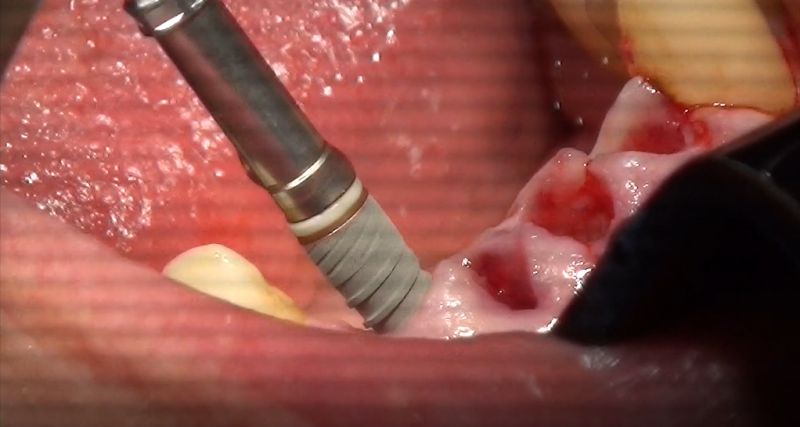

First, the dentist extracted teeth #31, #32, #41, and #42.

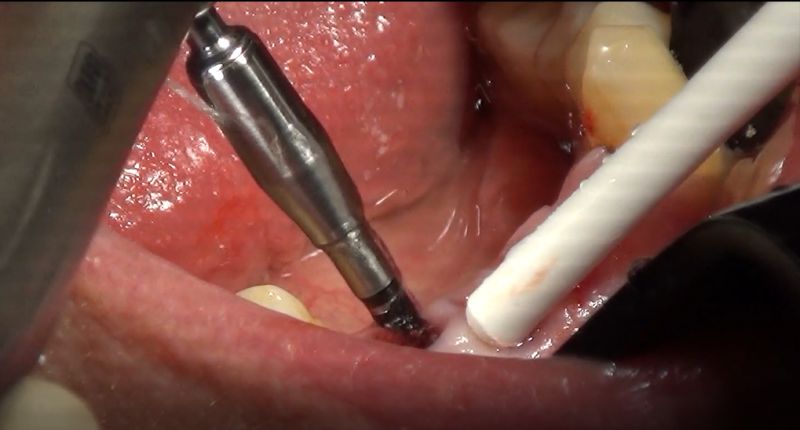

He then immediately placed implants on teeth positions #32 and #42.

3D scanning

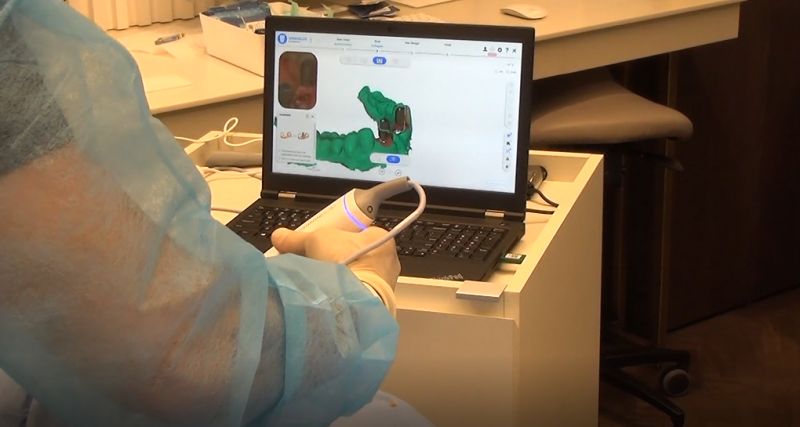

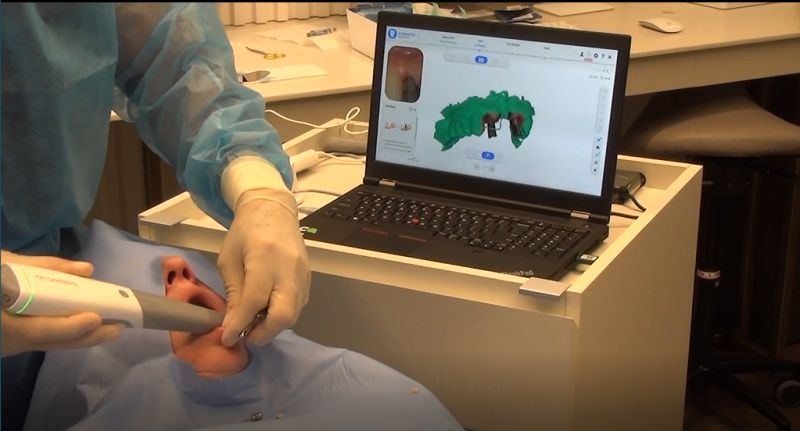

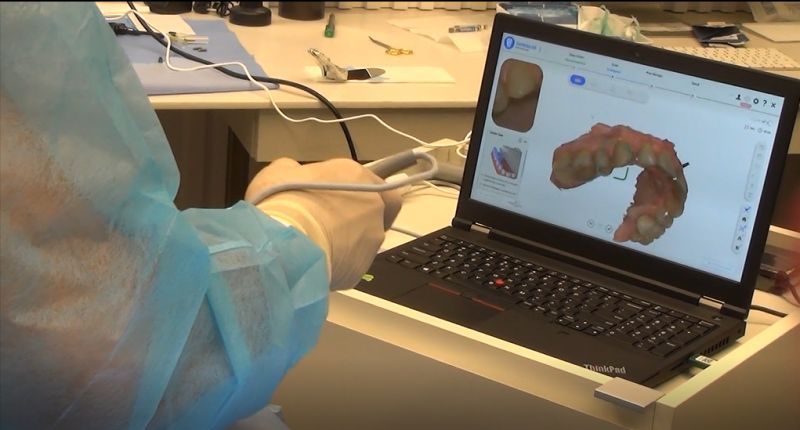

After surgery, we can immediately scan with SHINING 3D’s Aoralscan 3 intraoral scanner.

This process gives us a digital, 3D impression for subsequent model creation and restoration.

We first scan the upper arch as the antagonist.

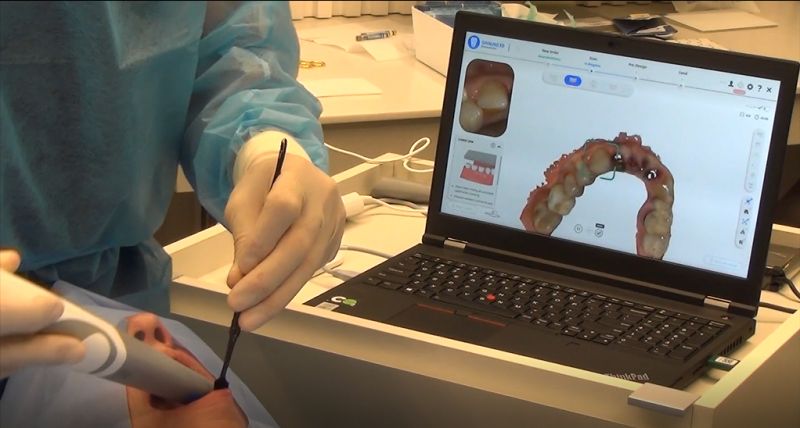

Then, we scan the lower arch without the scan body. This means less chair time and no contact with any impression material. It’s a more comfortable, less anxious experience for patients.

The “true color” feature also enables patients to see everything in their mouths.

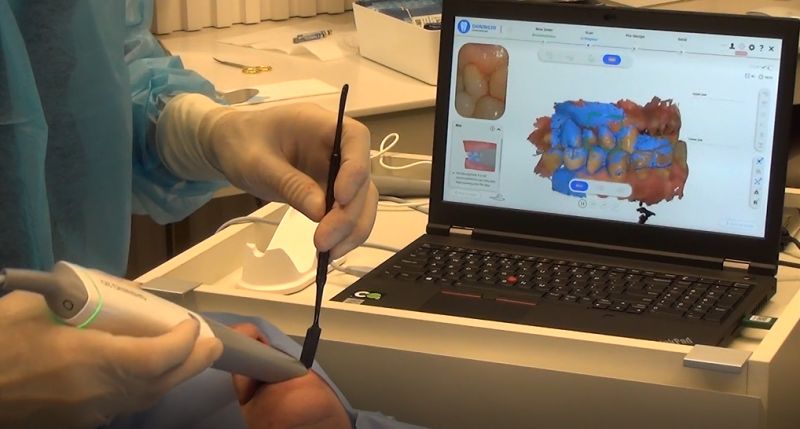

Once we have the impression without the scan body, we perform another 3D scan of the lower arch with the scan body. The “metal tooth scan” option enables a quick and efficient process despite the metallic material.

Then, we scan the bite to complete the digital impression. Next, the dentist can email the digital impression to the laboratory, rather than physically send a traditional impression tray.

Design and 3D printing

With the complete digital impression, we can design the restoration and dental models with high accuracy. We then print the models with the AccuFab-D1s, place the analog, and try the restoration on the printed model.

Final result

Finally, we can try the restoration in the patient’s mouth, tighten the screws, and block the screw channel with filling. Here is the result:

3D scanning in immediate loading is an efficient digital dentistry application. Contact our team today to find out how to implement our ecosystem in your clinic or lab.

ENG

ENG