Abstract

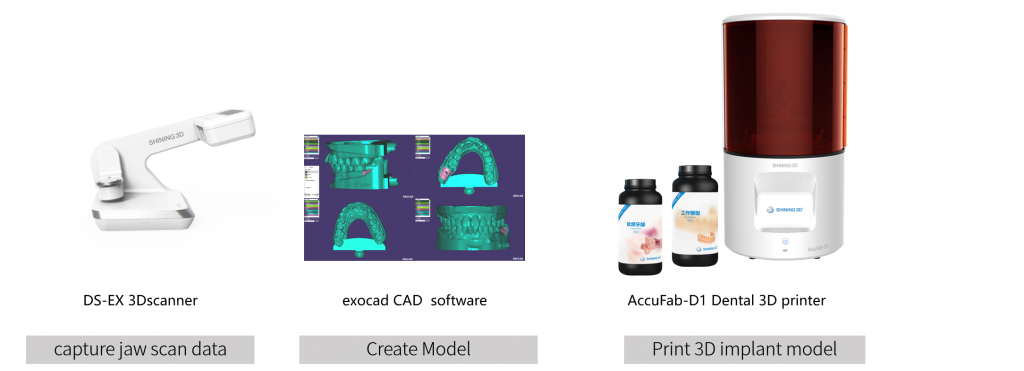

Nowadays, data transmission is commonly used and no logistic delivery is involved. Nonetheless, the actual models are still required in the subsequent process.

Thus, either virtual intraoral scanning data or impression scanning data is required for model creation and 3D printing.

Implants are one of the most common restoration types that adopt either intraoral or impression scans to acquire data for digital design and printing.

1. Data acquisition

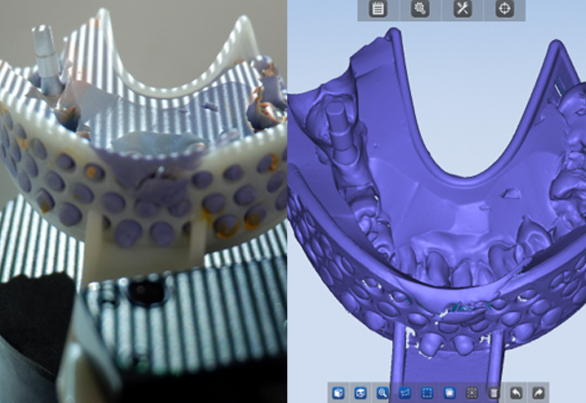

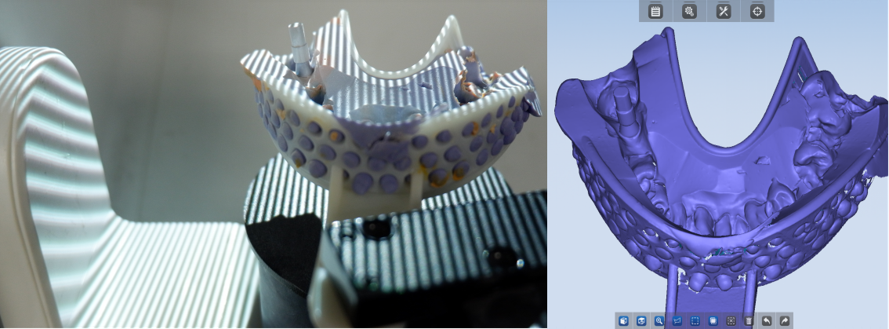

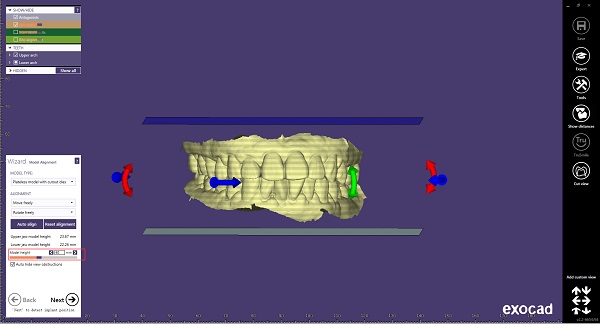

Utilize the DS-EX scanner (impression scan) to obtain the “jaw scan” data.

Note: Make sure the characteristic face is on the buccal or lingual side for complete acquisition.

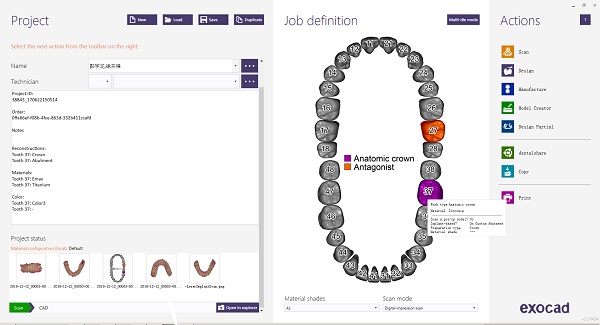

2. Load 3D data

Open Exocad software and click “Load”. Then, select to load the data.

Data requirements:

A. Upper jaw and lower jaw are in occlusion & Scanbody is captured completely.

B. Adjacent teeth should be redefined into antagonists after loading the data

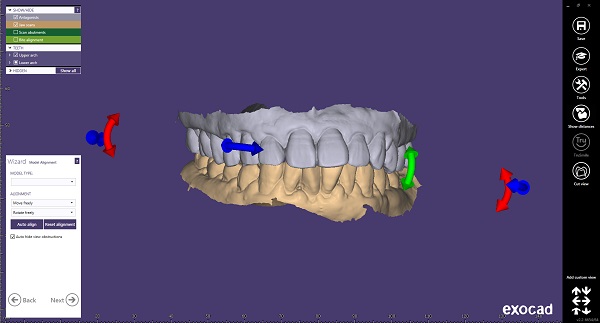

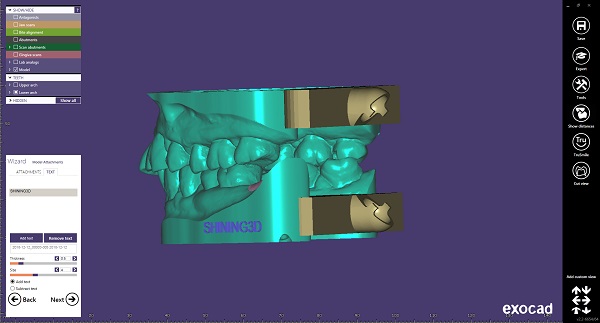

3. Design

(1) Select “model type” & define the “model height”

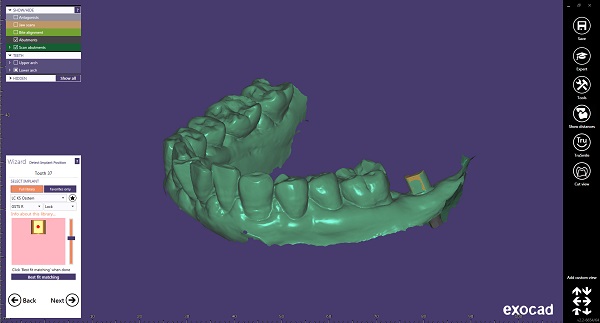

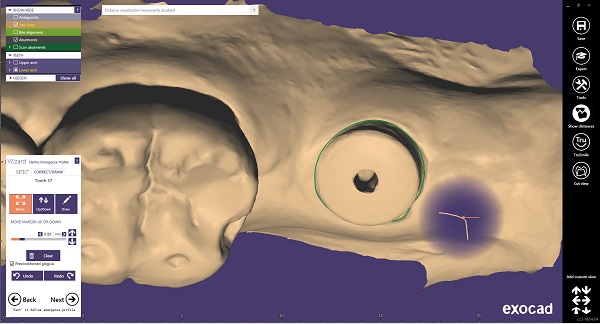

(2) Detect implant position

(3) Edit 3D data

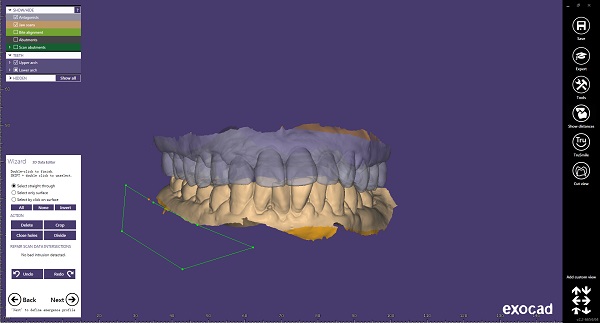

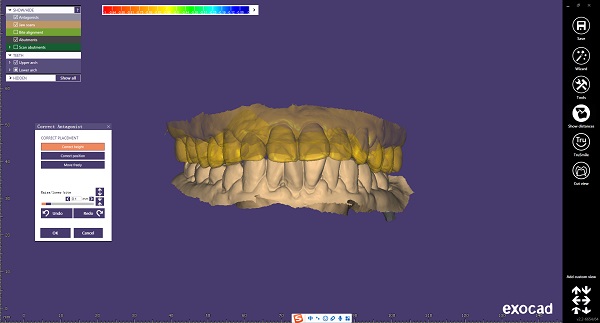

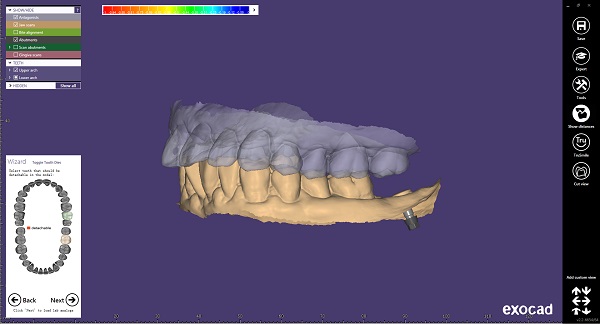

(4) Correct placement of antagonist

(5) Define emergence profile

(6) Select teeth that should be detachable

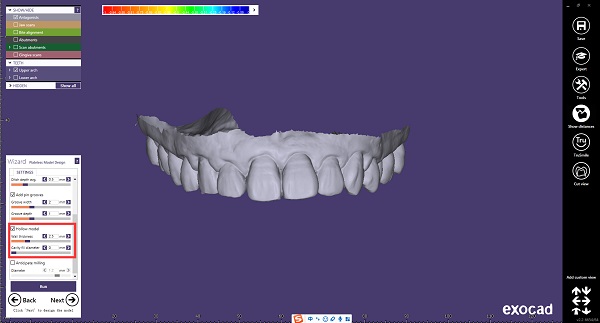

(7) Opposite model design , check the option “hollow model “for saving material

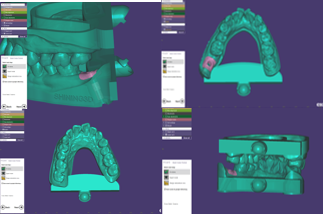

(8) Working model design , define the gingiva mask

(9) Add model attachments and text

(10) Finish model creator

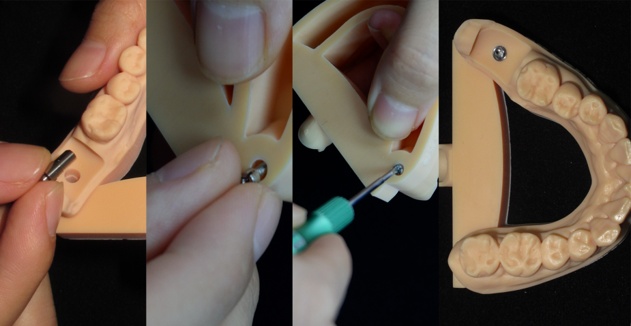

3. Printing & Assembly

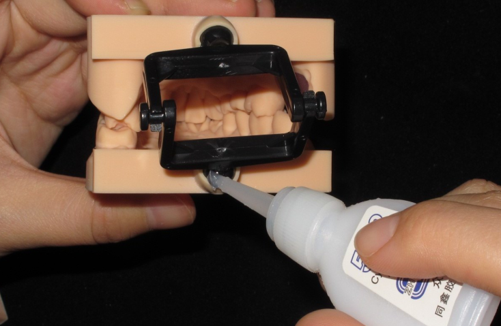

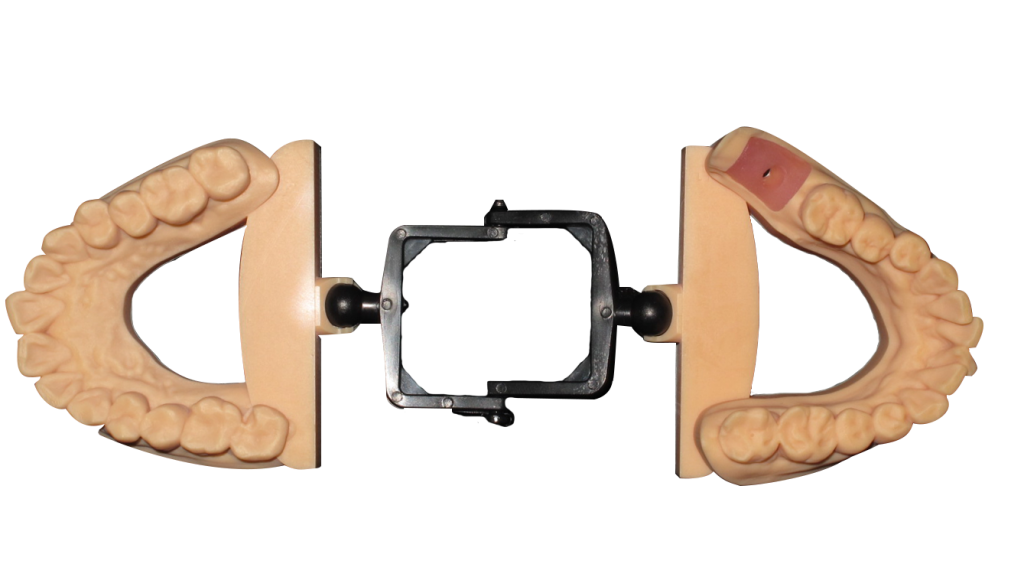

(1) Place the analog

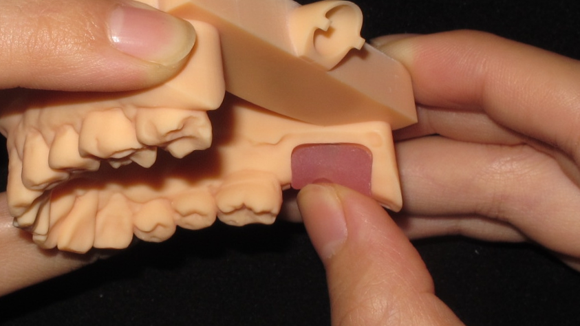

(2) Place gingiva mask

(3) Assemble the simple articulator

4. Complete

4. Complete

Solution for 3D implant Model

ENG

ENG