Dr. Chen Qingsheng details his full dentistry workflow of implant case with the AoralScan intraoral scanner and AccuFab-D1 3D printer.

Introduction

Nowadays, digital implant restoration is becoming more popular with technological improvements in dentistry.

In this clinical case, we display an integrated digital implant restoration workflow using the SHINING 3D intraoral scanner, Aoralscan, and 3D printer, AccuFab-D1.

This digital workflow not only provides more comfort to patients, but also improves the work efficiency of the dental practitioners, saving the trouble of making physical impressions and models.

Case Information

- Procedure: Single crown based on implant restoration

- Dentist: Chen Qingsheng, Hangzhou Hospital of Stomatology

- Patient: Female

- Dental History: Missing teeth #24 & #46

- Treatment Plan: Implant crown restoration #24 & #46

- Implant System: OSSTEM 4.5×10mm RN

- Restoration System: Customized abutment + Zirconia full crown.

- Dental Laboratory: Fuzhou World Medical Technology Co., Ltd.

- Solution integrates: Aoralscan Intraoral Scanner, AccuFab-D1 Dental 3D Printer

Workflow

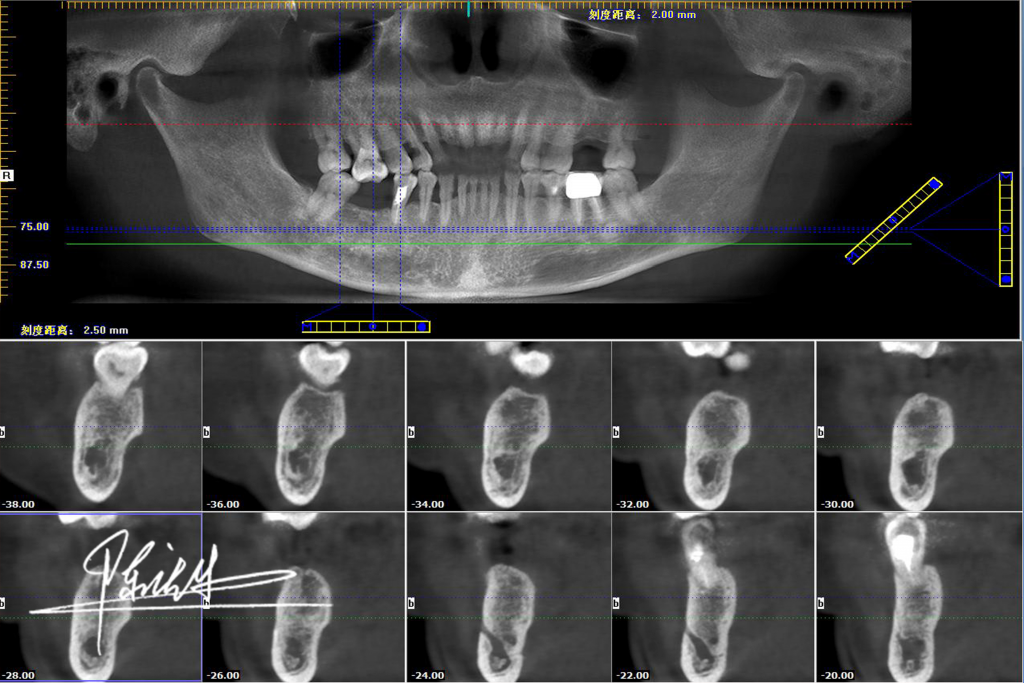

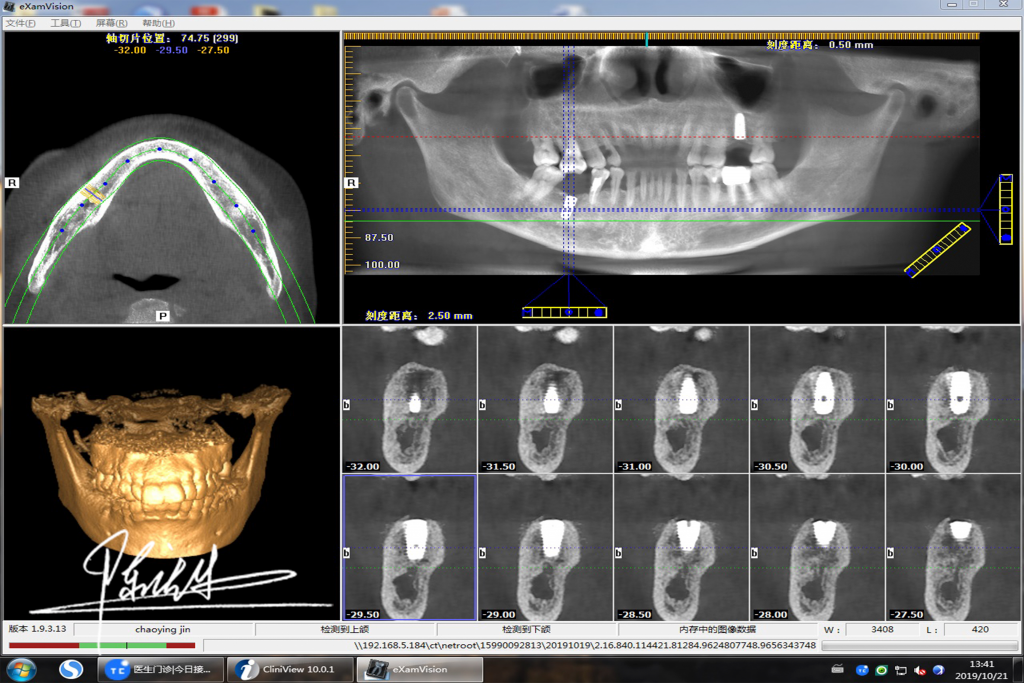

1. Pre-op Examination

The first step was to perform Radiographic Examination (CBCT) before surgery, CBCT result shows the amount residual bone is acceptable for an implant.

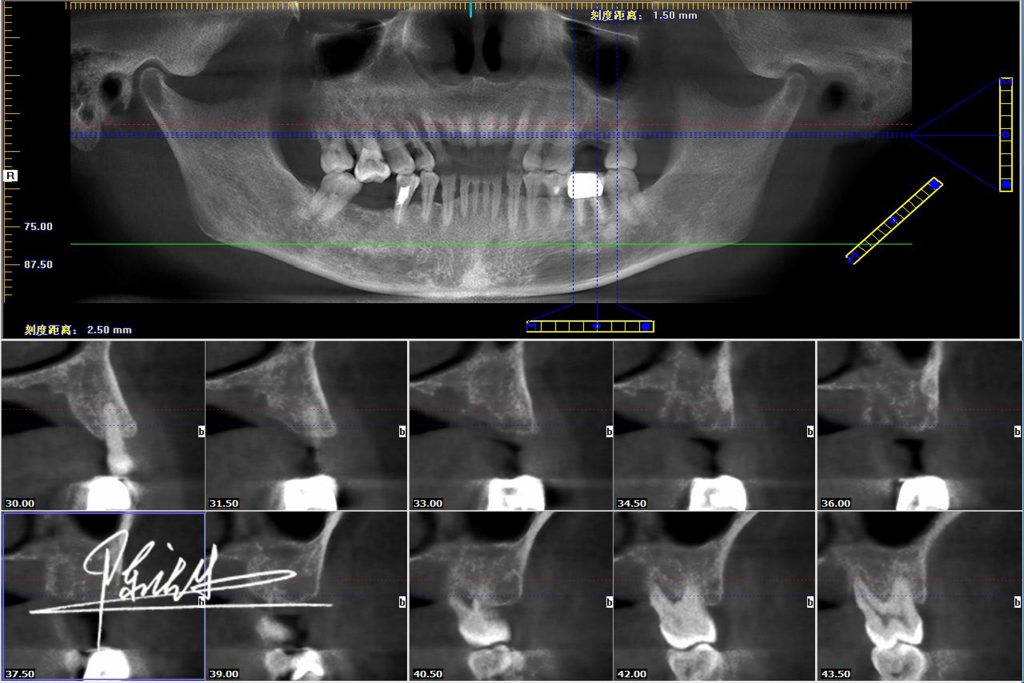

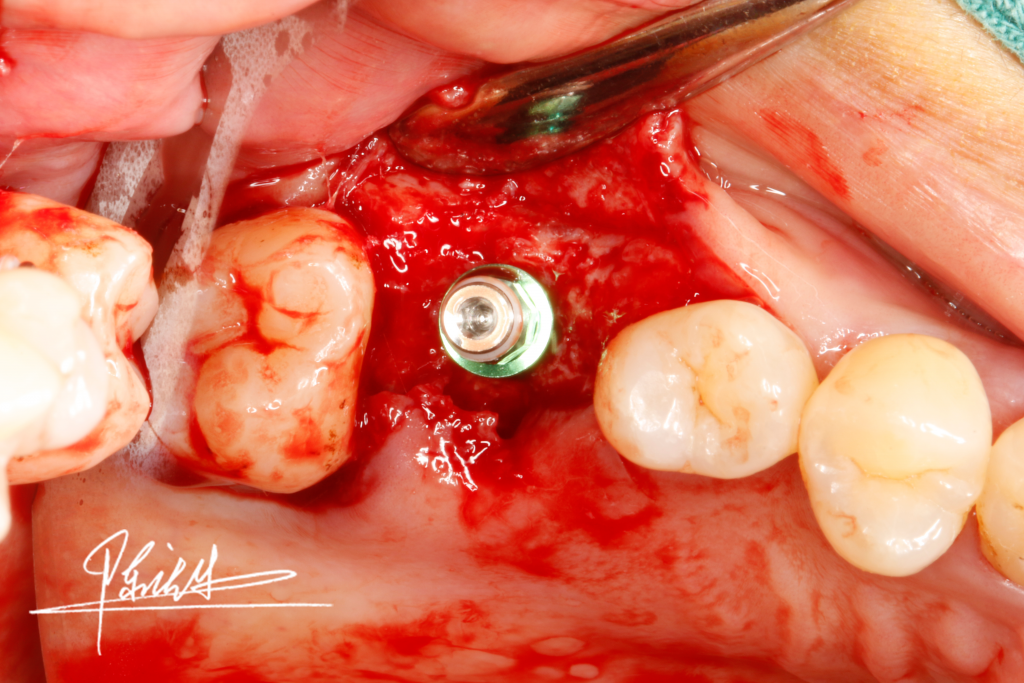

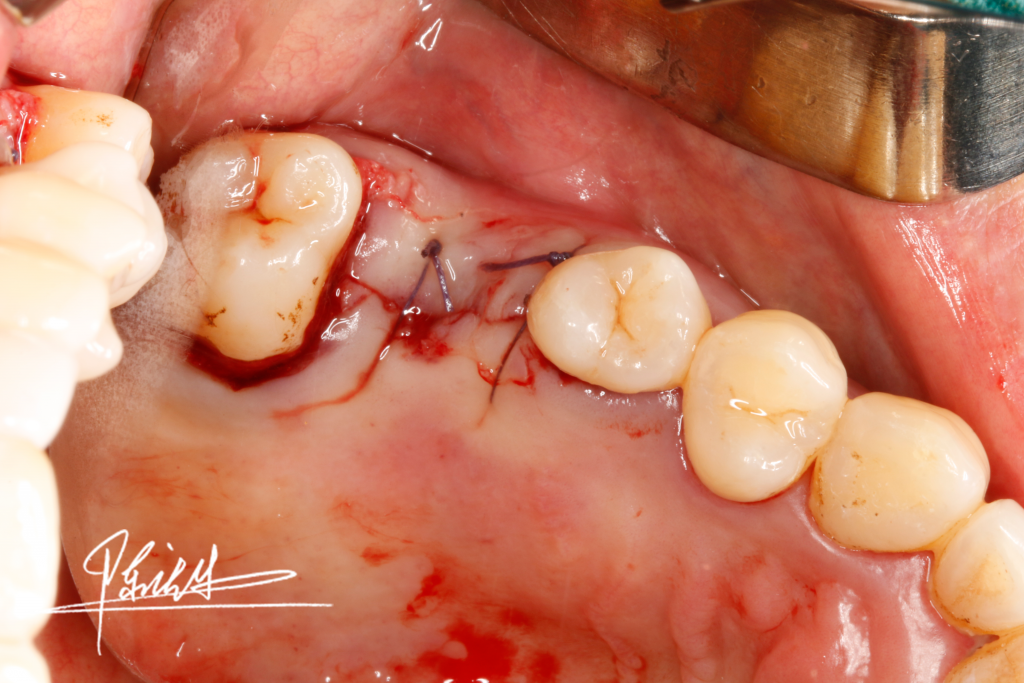

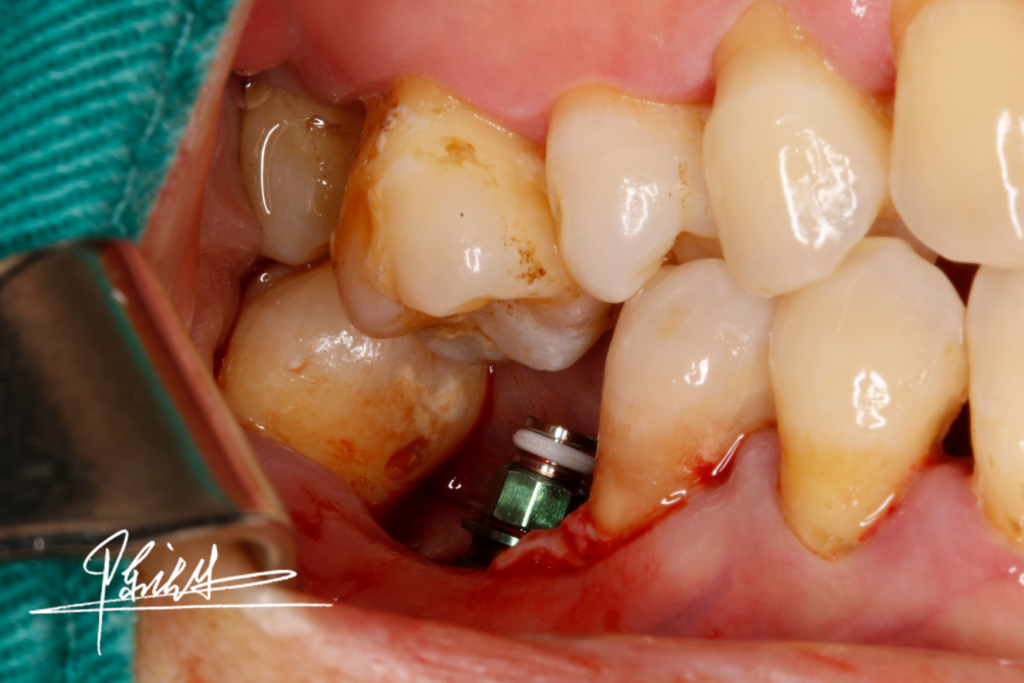

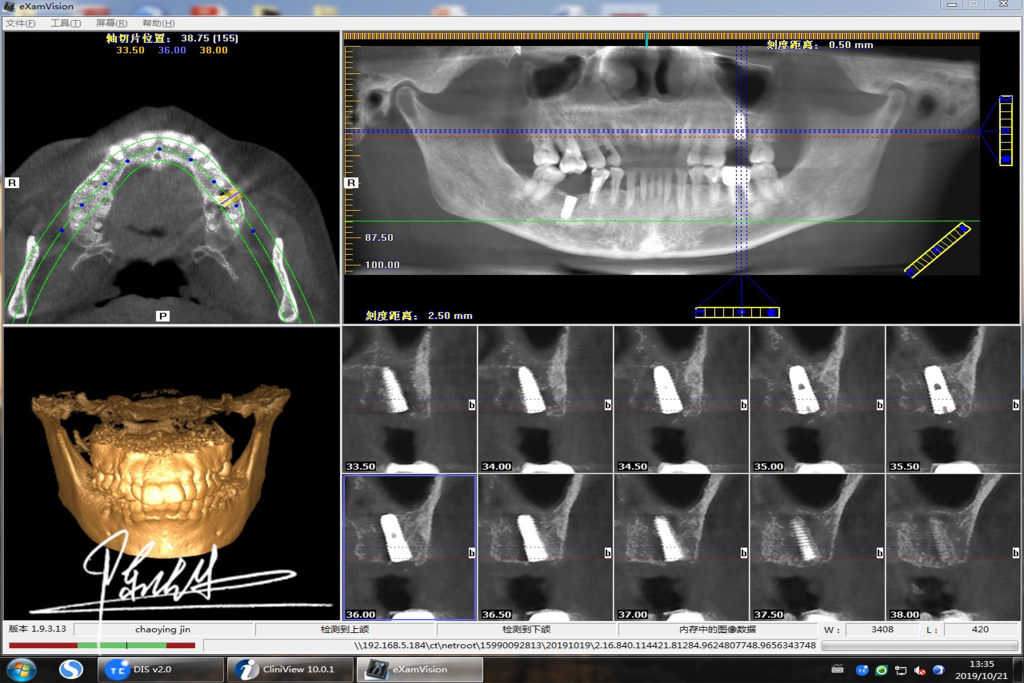

2. Implant Surgery

Implant bed preparation: placing the OSSTEM 4.5×10mm RN implant; the 3D position of the implant was accurate and the initial stability is ideal.

Radiographic Examination-CBCT after surgery: the 3-dimensional position of implant is accurate.

3. Acquire digital impression

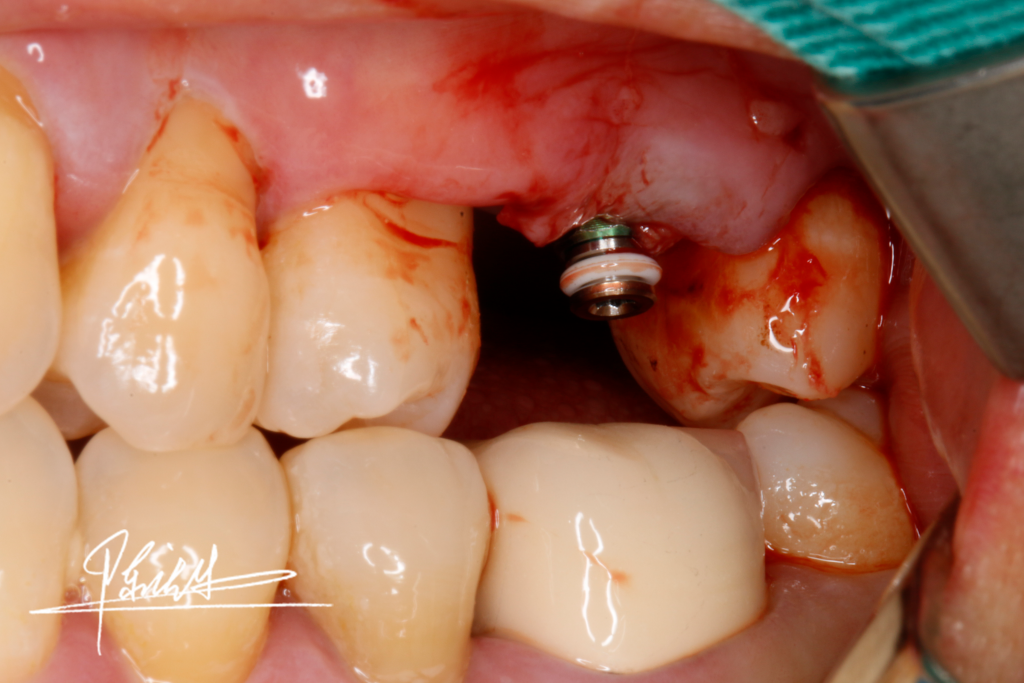

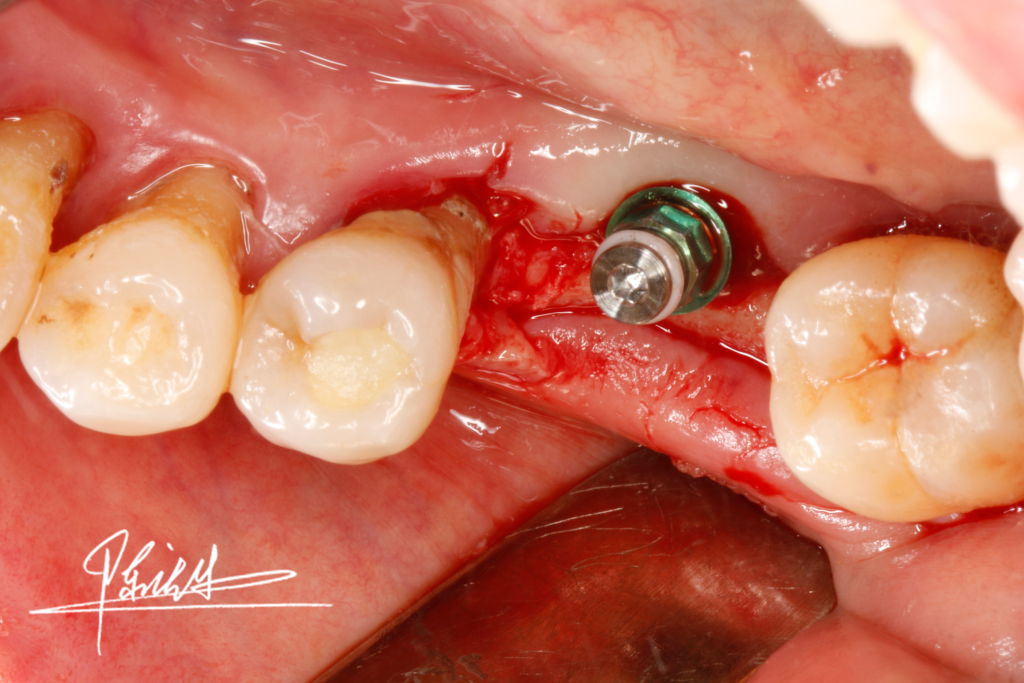

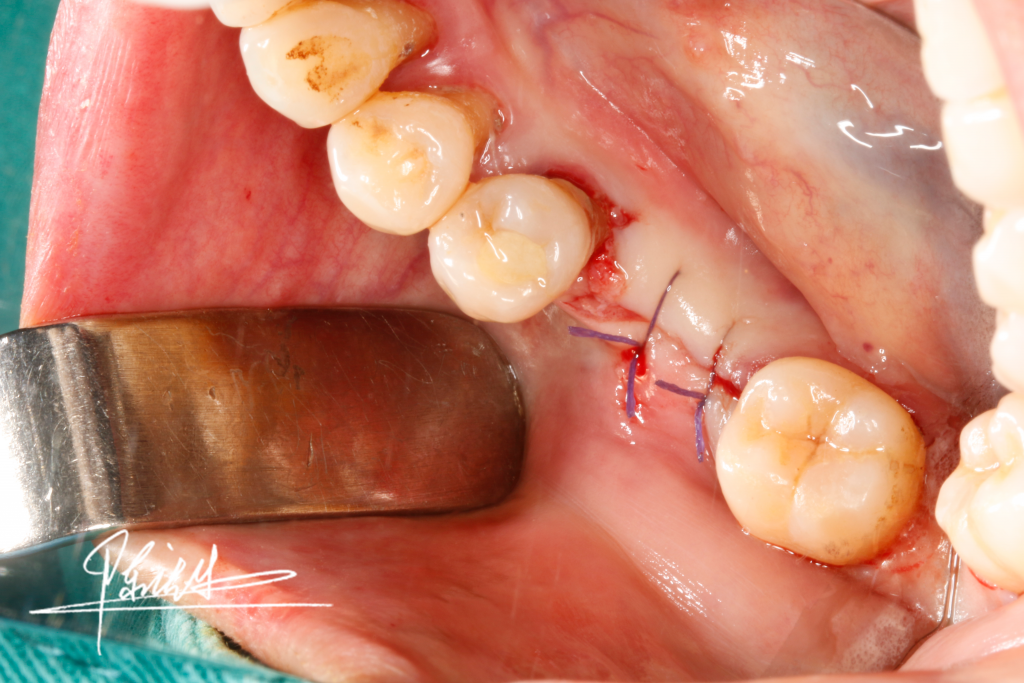

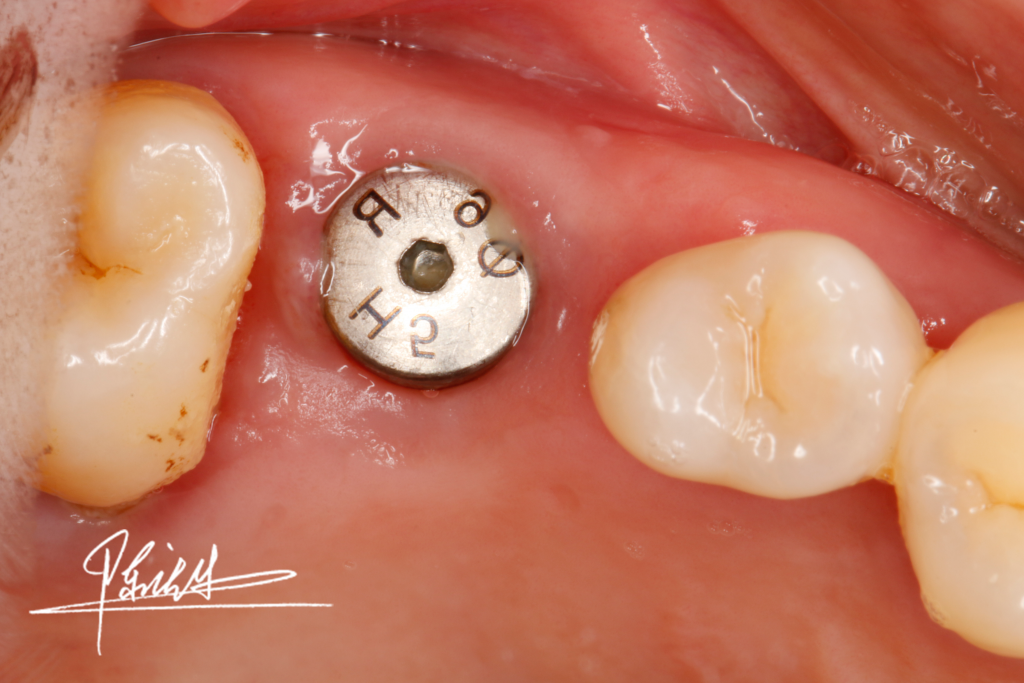

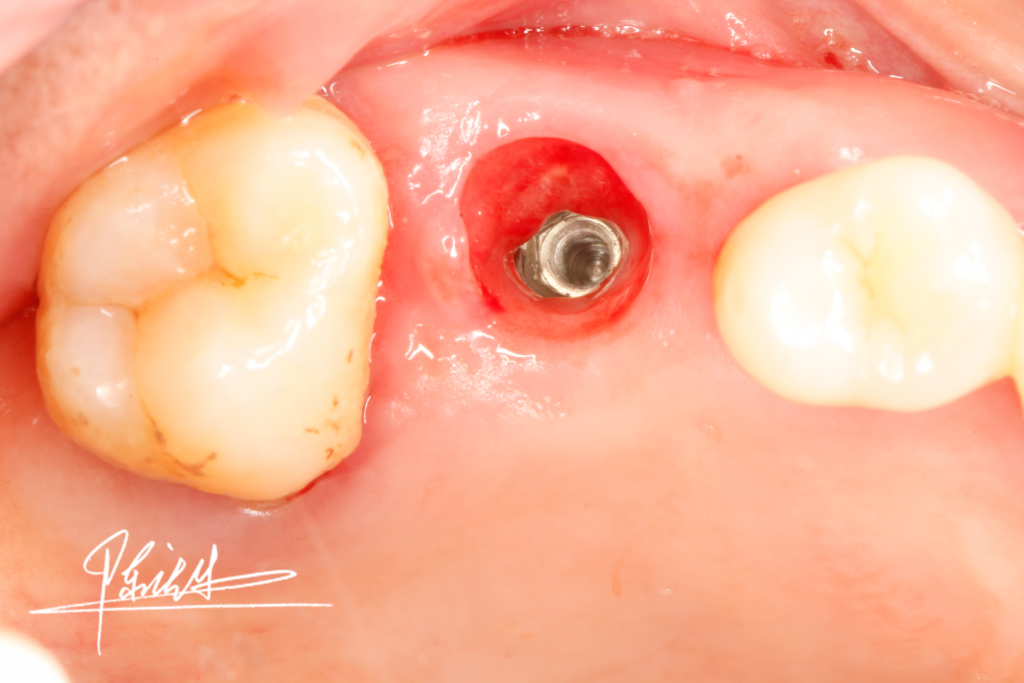

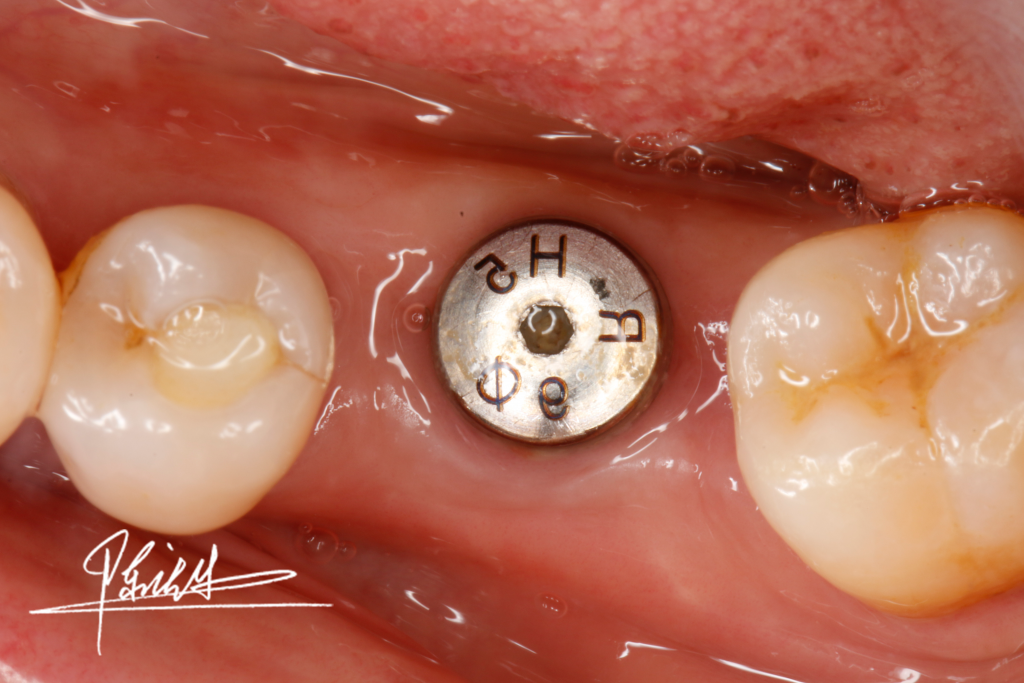

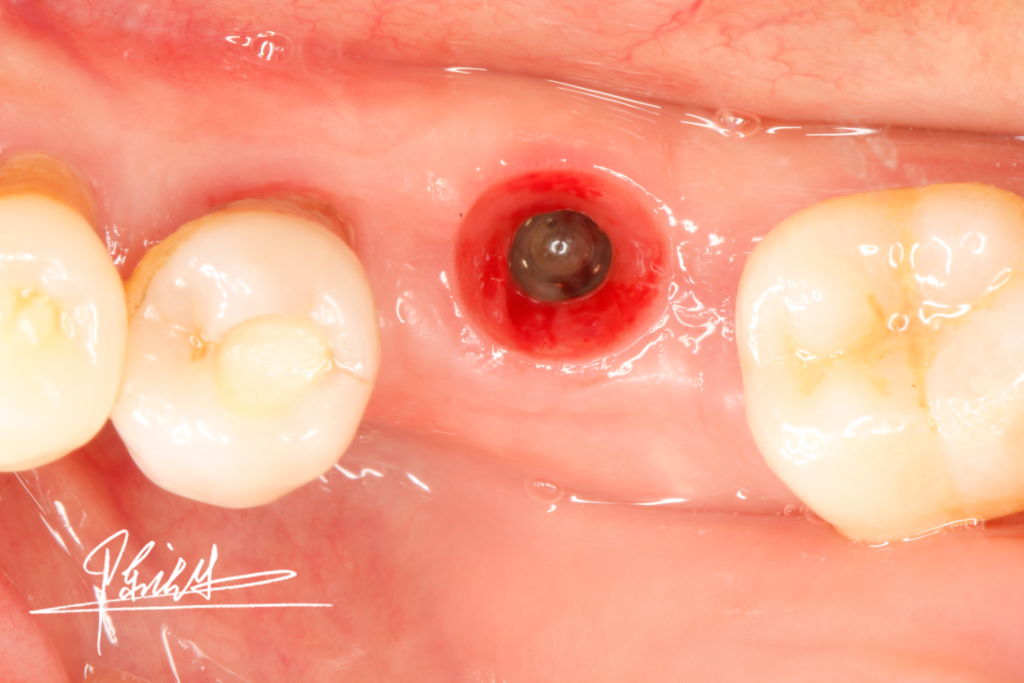

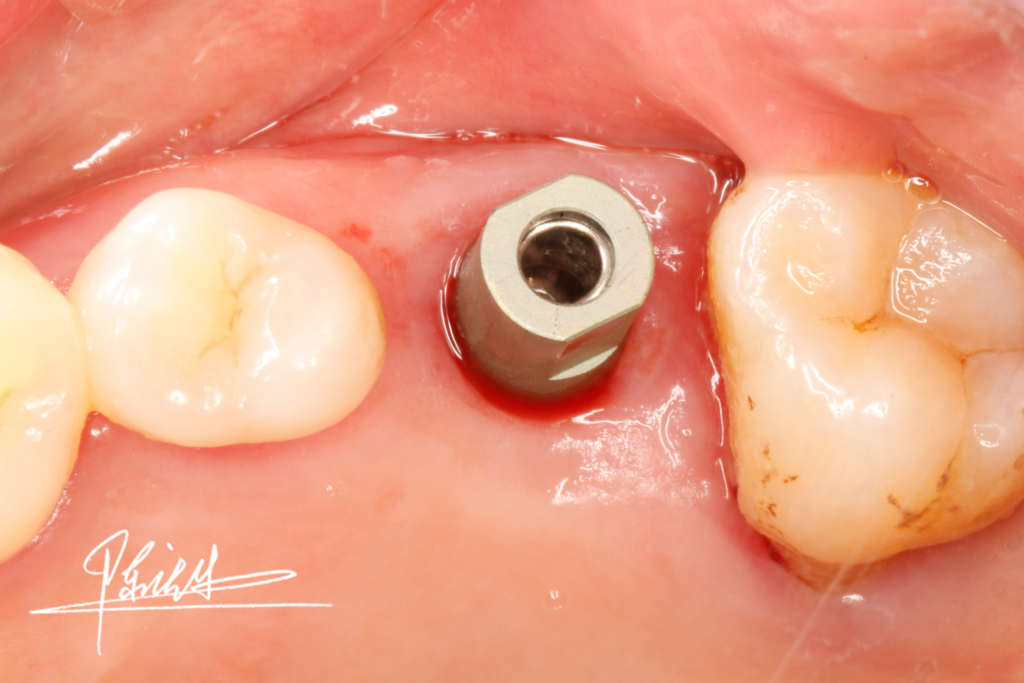

Finish the Tissue Sculpting

After the 3 months of gingiva healing period, we obtained a good tissue contour and morphology. We proceed to obtain the digital impression by using the intraoral scanner and fabricate the restorations.

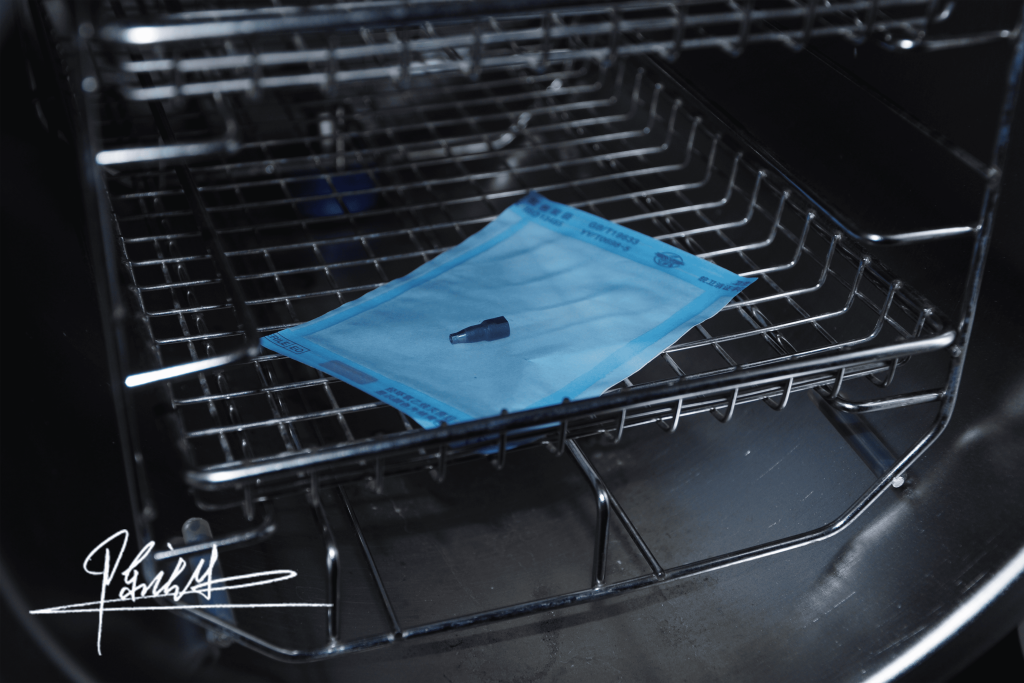

Scan Body Sterilization

Disinfection of the scan bodies is crucial before proceeding to obtain the digital impression. Rinsing the scan body for 5mins before placing it into the sterilizer cabinet at 121℃1.5 atm for 15mins (the scan body should be placed inside a sterilized bag).

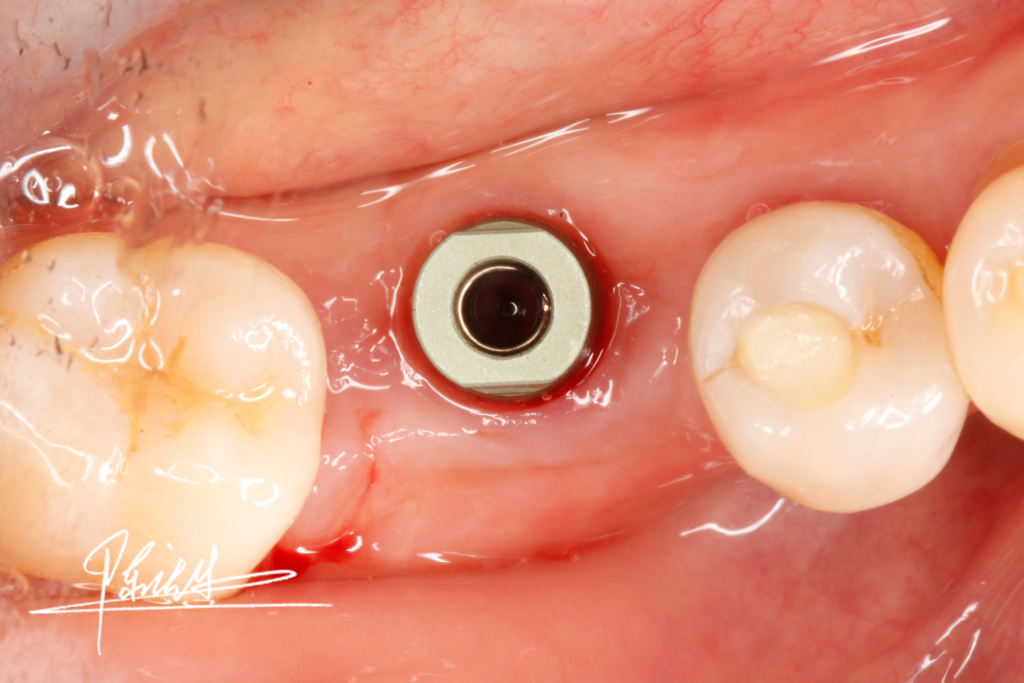

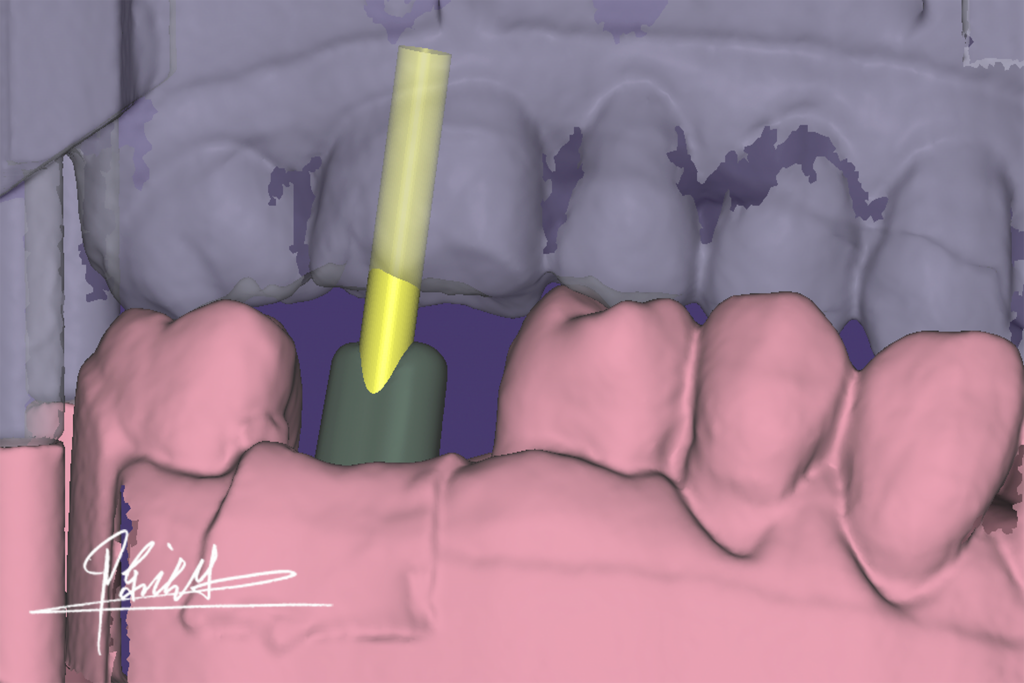

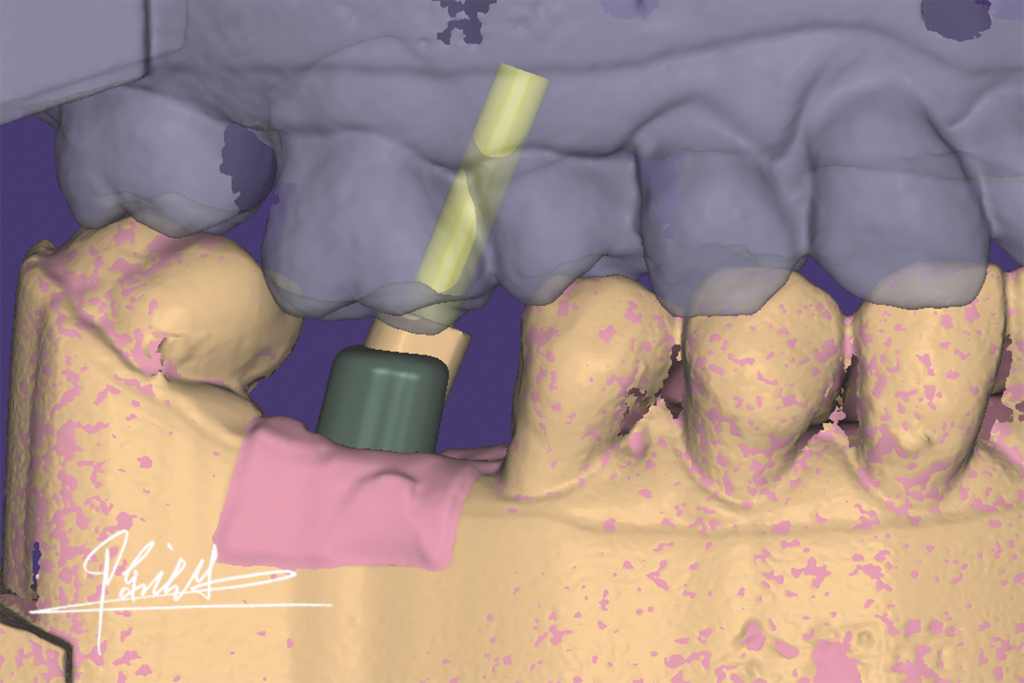

Scan Body Try-in

Fit the sterilized scan body on the abutment inside the mouth, check the placement of the scan body carefully. X-Ray examination can be applied if necessary.

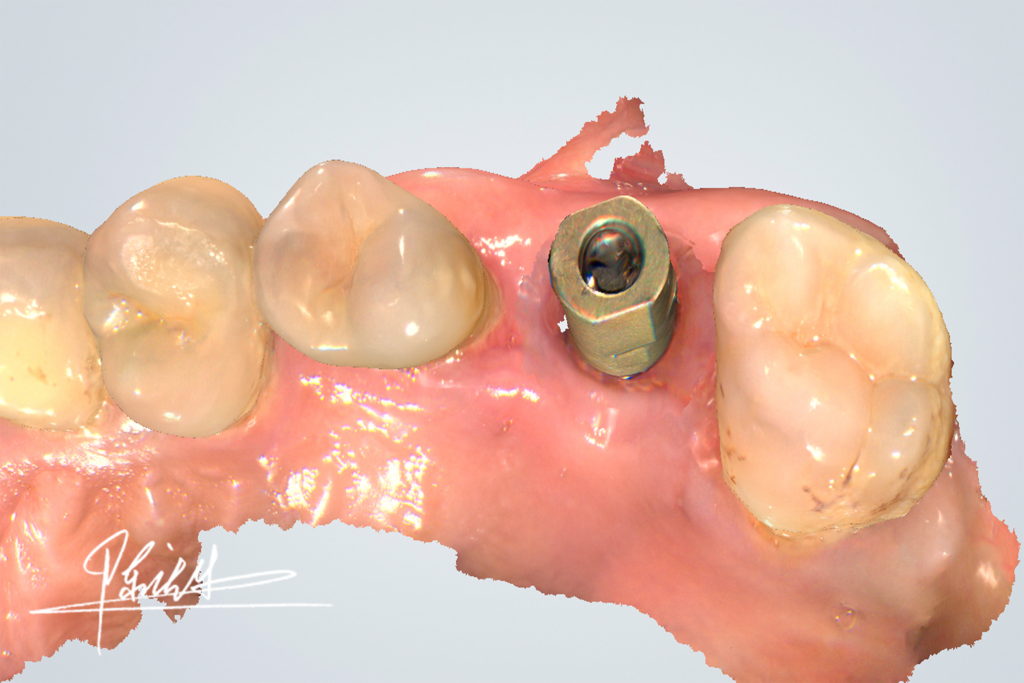

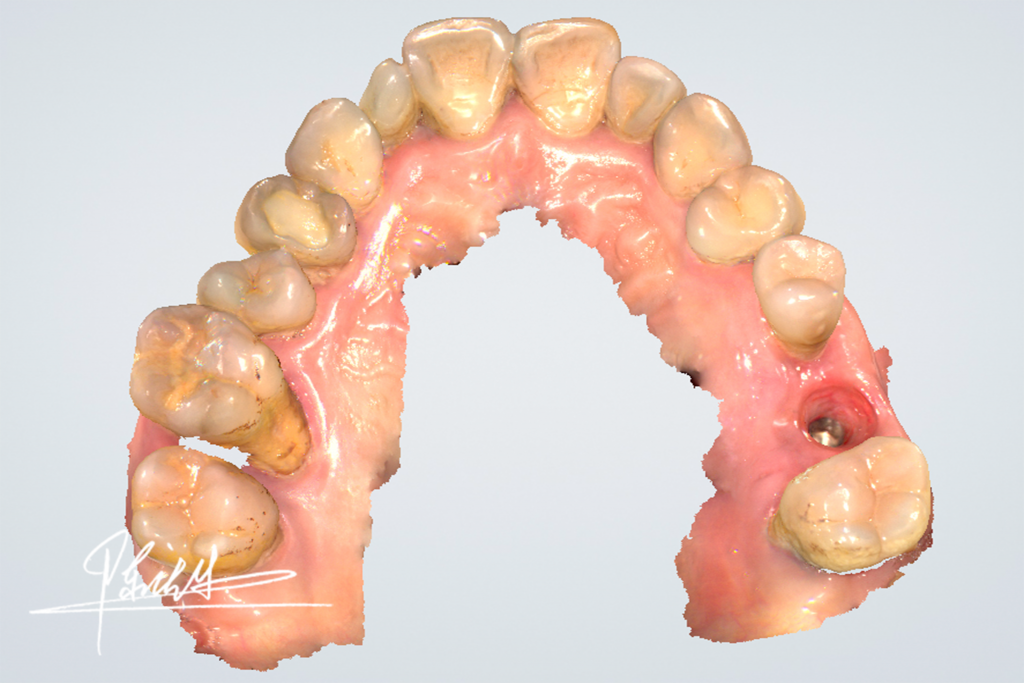

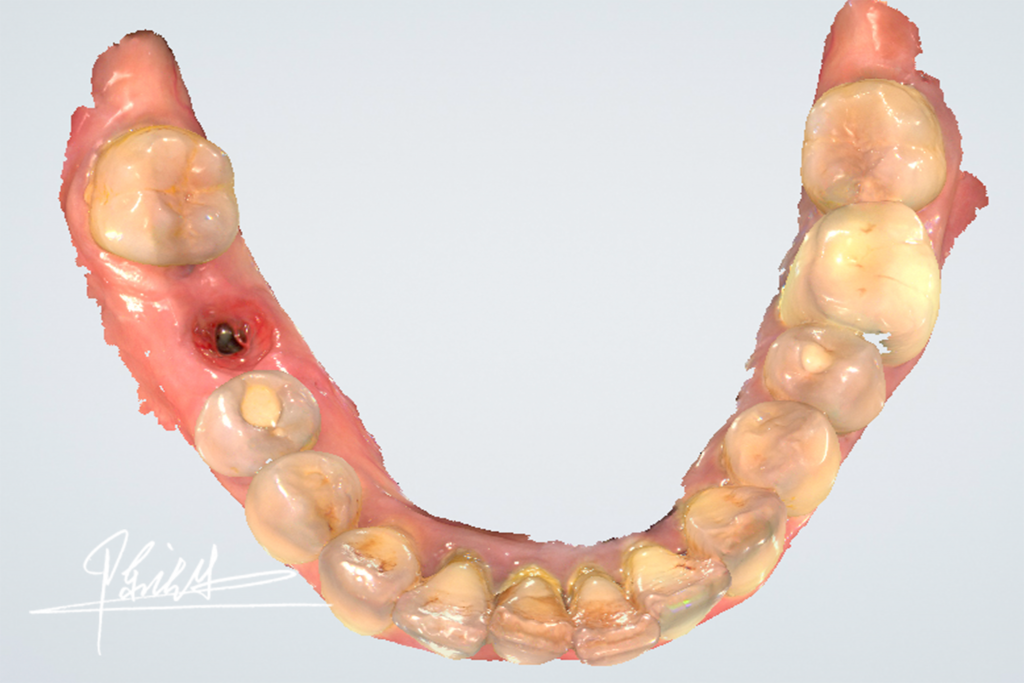

Acquire intra-oral Data

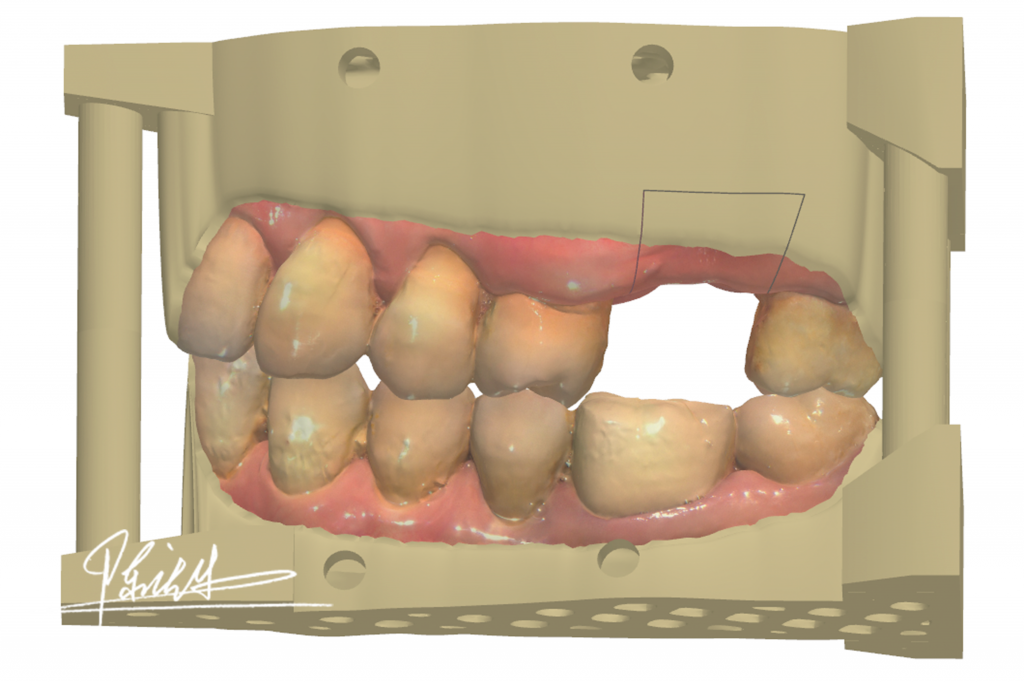

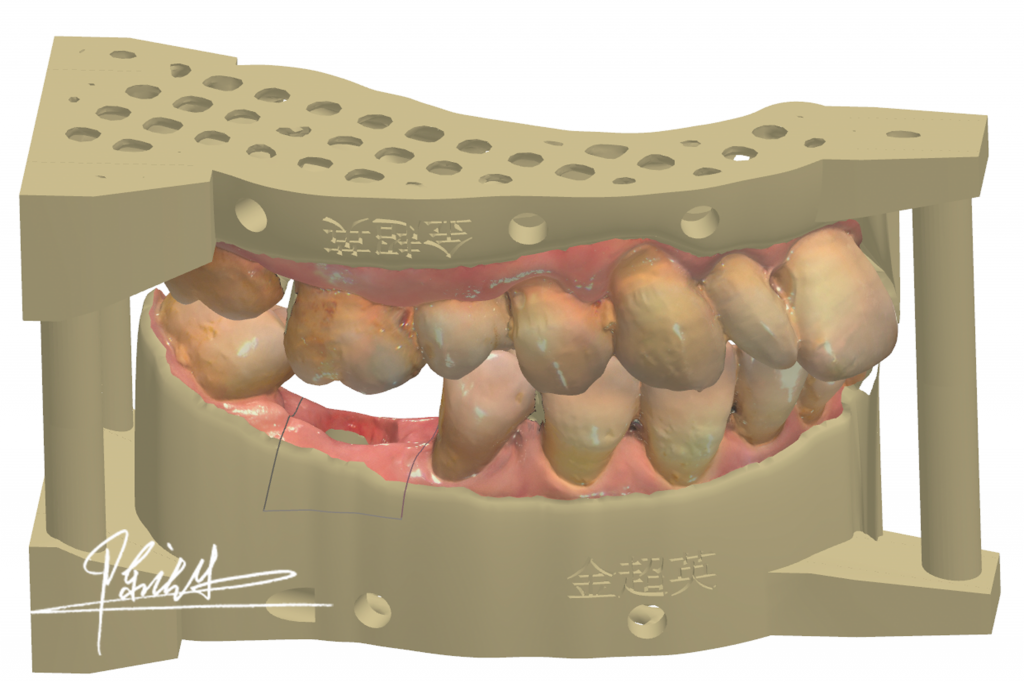

We use the Aoralscan to obtain the digital impression of upper and lower arch, instead of conventional impressions. This method is more effective while also providing more comfort to patients.

4. CAD/CAM Prosthodontics

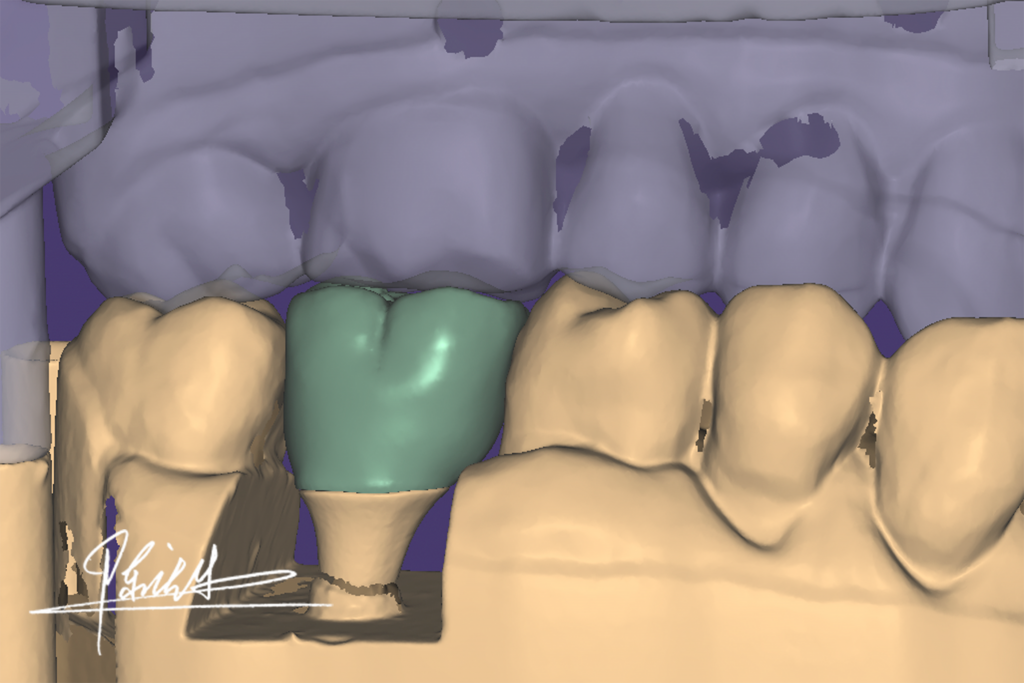

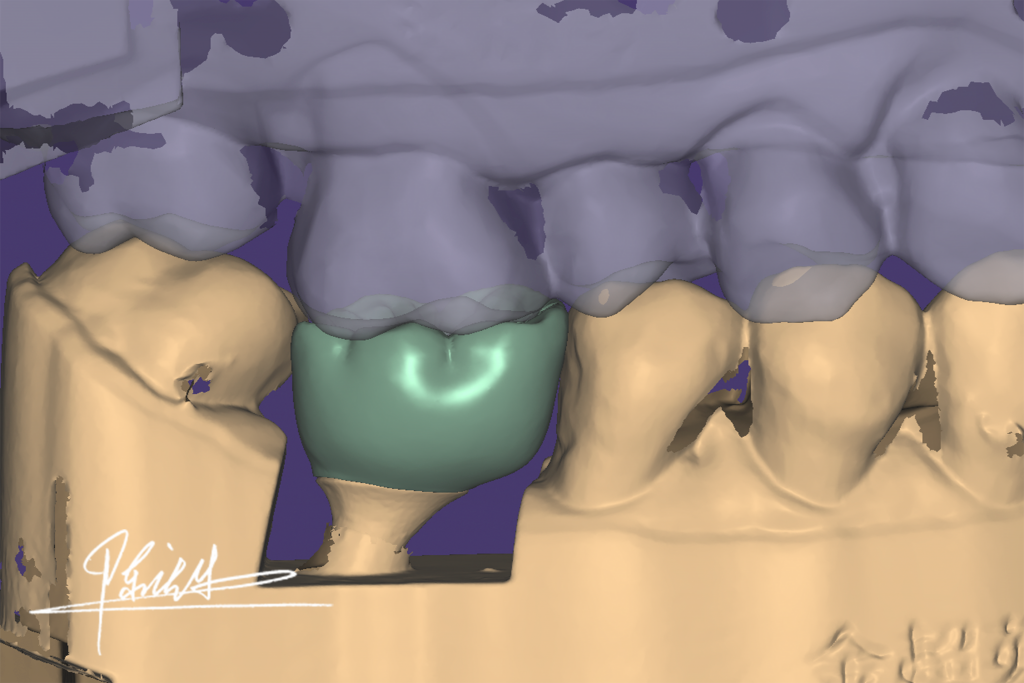

Design Implant Model

After that, the 3shape software was used to design the model based on the “ply” format data exported by SHINING 3D Aoralscan intraoral scanner. This information can be imported into 3shape so it displays the TrueColor effect.

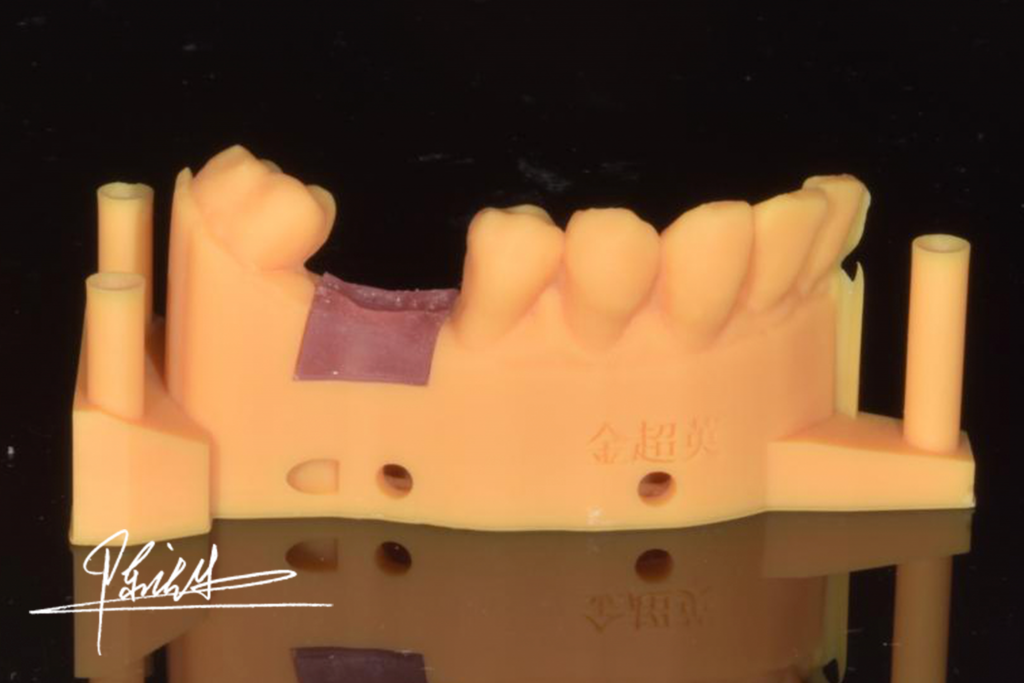

3D Print the Implant model

Then, the SHINIG 3D AccuFab-D1s 3D printer was utilized to fabricate the implant model.

Fabrication of the Customized Abutment

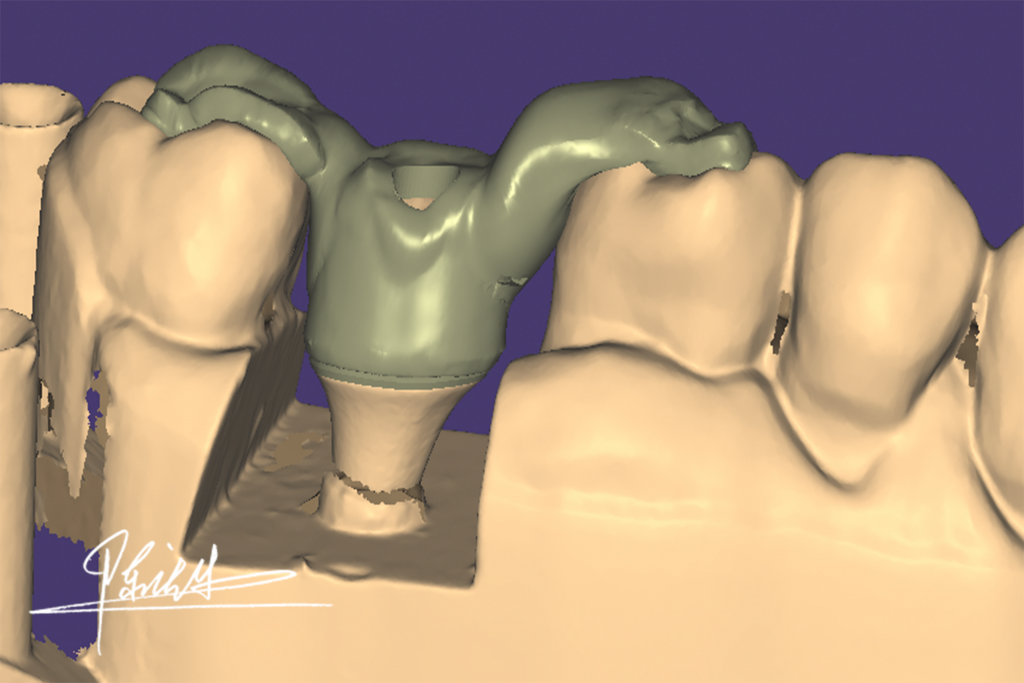

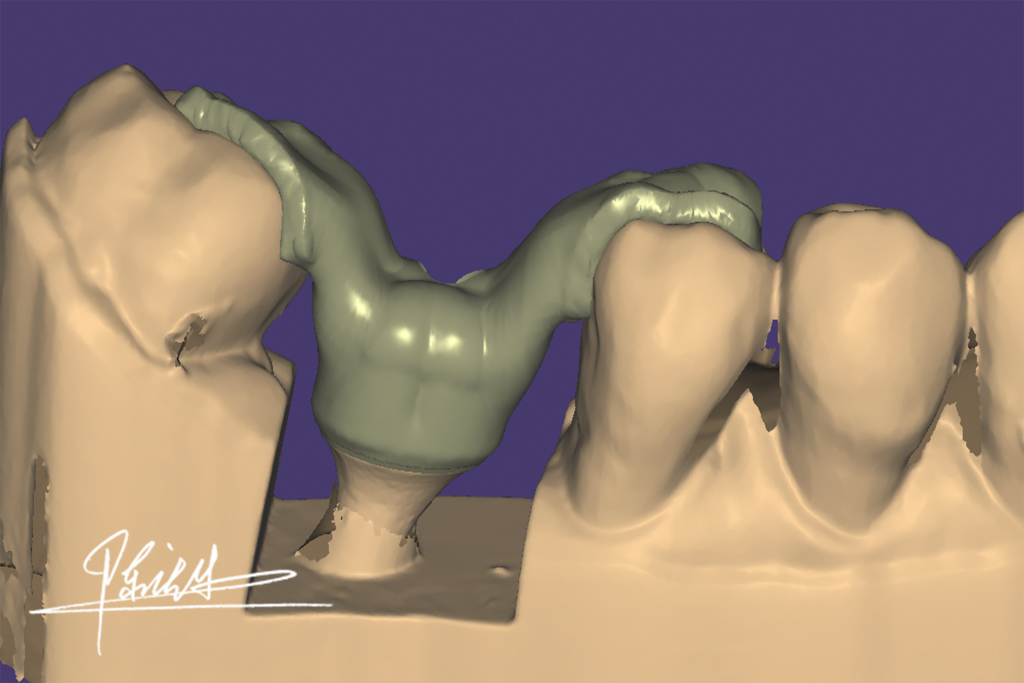

The customized abutment was designed in EXOCAD according to the digital model and milled afterwards

Manufacture the Zirconia Crown

EXOCAD was also used to design the Zirconia crown and fabrication of the crown by milling method.

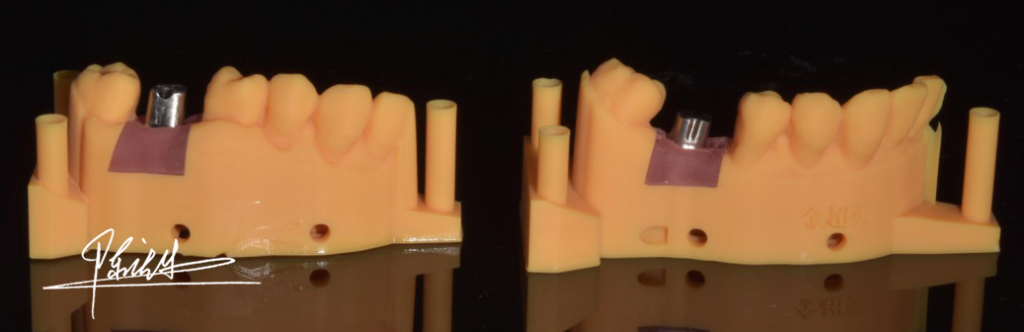

Fabricate the Implant Transfer Cap

Then, the team 3D printed the implant transfer cap along with the Zirconia crown with the SHINING 3D AccuFab-D1.

Finishing

5. Restorations Try-in

X-Ray examination was perfect when checking the accuracy of location, adjacency and occlusal relationship after place the final abutment and restorations.

About the Doctor

Associate chief physician. Master’s degree in implant dentistry. Director of the implant department in Hangzhou Dental Hospital (Chengxi branch). Member of Chinese Stomatological Association Restoration Committee, Chinese Stomatological Association Aesthetic Restoration Committee. Standing director of Chinese Association of Aesthetic Dentistry. Prize winners of various national implant competition.

Comments from the Doctor

The SHINING 3D Aoralscan is fast and effective way of duplicating a patient’s oral information with a high accuracy. Dental practitioners can easily obtain the ideal restorations when working with a professional CAD software and a dental milling machine. The integrated CAD/CAM system provided by SHINING 3D not only reduces the work time of clinicians on chairside, but also improves the satisfaction of patients. We look forward for this system to be widely used for clinical applications in the future.

ENG

ENG